BMW X3 (F25) Service & Repair Manual: Rear axle

- Adapter

- Basic body

- Bush

- Device

- Extension

- Fixture

- Frame

- Holder

- Holding sleeve

- Insert

- Mandrel

- Nut

- Plate

- Pliers

- Ring

- Rod

- Screw

- Shaped element

- Shaped part

- Shell

- Socket wrench

- Spindle

- Spring cups

- Spring tensioner

- Synchronising key

- Tool

- Washer

- Wrench

Adapter

Adapter AM

NOTE: Adapter M4 (Ø 96mm) in connection with adapter kit 2 (BMW), (81642155746), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Adapter AM

NOTE: Adapter R7 (M24/Ø 87/95mm) in connection with adapter kit F03 (81 64 2 348 804) for installation and removal of wheel bearings, propeller shafts and drive shafts.

SI number

08 02 13 (900)

Adapter AM

NOTE: Adapter P5 (/Ø 45/82.5mm) in connection with wheel bearing adapter kit F30 (84mm, no longer in Catalogue) for installation and removal of wheel bearings, propeller shafts and drive shafts.

SI number

08 09 12 (873)

Adapter AM

NOTE: Adapter N1 (Ø 49mm) in connection with adapter kit 2 (BMW), (81 64 2 155 746), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Adapter AM

NOTE: Adapter R6 (M24/Ø 63/75mm) in connection with adapter kit F30 (84mm wheel bearings) for installation and removal of wheel bearings, propeller shafts and drive shafts.

SI number

08 09 12 (873)

Adapter AM

NOTE: Adapter N4 (Ø 39mm) in connection with adapter kit 2 (BMW), (81 64 2 155 746), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Adapter Mechanical tool

NOTE: For installing the rear axle shaft

Storage Location

X4

Adapter Mechanical tool

NOTE: For installing the rear axle shaft

Storage Location

X4

Adapter AM

NOTE: Adapter M2 (Ø 88mm) in connection with adapter kit 2 (BMW), (81 64 2 155 746), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Adapter AM

NOTE: Adapter M8 for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Adapter AM

NOTE: Adapter P3 (Ø 39/72mm) in connection with adapter kit 2 (BMW), (81 64 2 155 746), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Adapter AM

NOTE: Adapter R3 (M24/Ø 69/79mm) in connection with adapter kit 2 (BMW), (81 64 2 155 746), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Adapter AM

NOTE: Adapter R8 (M24/Ø 74/83mm) in connection with adapter kit F03 (81642348804) for installation and removal of wheel bearings, propeller shafts and drive shafts.

SI number

08 02 13 (900)

Adapter AM

NOTE: Adapter P6 (/Ø 51/89mm) in connection with adapter kit F03 (81 64 2 348 804) for installation and removal of wheel bearings, propeller shafts and drive shafts.

SI number

08 02 13 (900)

Adapter AM

NOTE: Adapter P1 (Ø 45/85mm) in connection with adapter kit 2 (BMW), (81 64 2 155 746), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Adapter AM

NOTE: Adapter P4 (Ø 42/75 mm) in combination with adapter kit 2 BMW (81 64 2 155 746) for removing and installing wheel bearings, output shafts and drive flanges.

SI number

08 06 09 (544)

Adapter AM

NOTE: Adapter Z1 to attach torque wrench. Used in connection with hydraulic cylinder, (81642156246), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 04 12 (797)

Adapter AM

NOTE: Adapter set F03 as a supplement to the hydraulic tool for removal and installation of wheel bearings, output shafts and drive flanges.

SI number

08 02 13 (900)

Consisting of:

1 = 2348430

3 = 2348432

5 = 2348434

4 = 2348436

2 = 2348431

Adapter AM

NOTE: Adapter R4 (M24/Ø 64/75mm) in connection with adapter kit 2 (BMW), (81 64 2 155 746), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Adapter AM

NOTE: Adapter R2 (M24 tapered) in connection with adapter kit 2 (BMW), (81 64 2 155 746), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Adapter AM

NOTE: Adapter M6 (Ø 102/113mm) in connection with adapter kit 2 (BMW), (81 64 2 155 746), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Adapter AM

NOTE: Adapter N5 (/Ø 51mm) in connection with adapter kit F03 (81642348804) for installation and removal of wheel bearings, propeller shafts and drive shafts.

SI number

08 02 13 (900)

Adapter AM

NOTE: Adapter H2 (tooth finder) in combination with adapter kit 1 BMW (81 64 2 155 745) for removal and installation of wheel bearings, output shafts and drive flanges.

SI number

08 06 09 (544)

Adapter AM

NOTE: Adapter N2 (Ø 45mm) in connection with adapter kit 2 (BMW), (81 64 2 155 746), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Adapter AM

NOTE: Adapter P2 (Ø 49/90mm) in connection with adapter kit 2 (BMW) and adapter kit 3 RR for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Adapter AM

NOTE: Adapter B1 in connection with adapter kit 1 (BMW), (81 64 2 155 745) and MINI adapter kit (81 64 2 294 517), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Adapter AM

NOTE: Adapter R5 (M24/Ø 59/70mm) in connection with adapter kit 2 (BMW), (81 64 2 155 746), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Adapter AM

NOTE: (adapter with nut and washer)

Storage Location: Z3

Z4

Adapter AM

NOTE: Adapter N3 (Ø 42mm) in connection with adapter kit 2 (BMW), (81 64 2 155 746), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Adapter AM

NOTE: Adapter M5 (Ø 90mm) in connection with adapter kit 2 (BMW), (81 64 2 155 746), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Adapter AM

NOTE: Adapter M1 (Ø 100/101mm) in connection with adapter kit 2 (BMW), (81 64 2 155 746), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Adapter AM

NOTE: Adapter M3 (Ø 102mm) for installation and removal of wheel bearings, propeller shafts and drive shafts.

SI number

08 06 09 (544)

Adapter AM

NOTE: Adapter G3 (M27x1.5/M20) in connection with adapter kit 1 (BMW), (81 64 2 155 745), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Adapter AM

NOTE: Adapter E2 (M24) in connection with adapter kit 1 (BMW), (81 64 2 155 745), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Adapter AM

NOTE: Adapter G2 (M24x1.5/M20) in connection with adapter kit 1 (BMW), (81 64 2 155 745), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Adapter AM

NOTE: Adapter R1 (M24/Ø 77/82mm) in connection with adapter kit 2 (BMW), (81 64 2 155 746), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Adapter AM

NOTE: Adapter G1 (M22x1.5/M20) in connection with adapter kit 1 (BMW), (81 64 2 155 745), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Basic body

Basic body AM

NOTE: No longer available separately, only available as part of complete tool set 0493416 = 33 4 400.

Basic body Minimum set: Mechanical tools AM

NOTE: Only available via complete tool set 33 5 120 -> (83 30 0 495 851).

SI number

01 22 06 (307)

BASIC UNIT

Basic unit AM

Replaced by: 83300492436

NOTE: Discontinuation and replaced by 33 4 200. (0 492 436)

BELT

Belt AM

NOTE: (Tensioning strap)

BRACE

Minimum set: Mechanical tools Brace AM

NOTE: Applies to: BMW i Aftersales Basic contour-graphic silhouette foil is included in the delivery specification.

Storage Location

B36

SI number

01 13 13 (968)

BRIDGE

Bridge AM

NOTE: (Support bridge)

Bush

Bush Mechanical tool

Replaced by: 83300492341

NOTE: (Impact bush) For radial seal on output flange - Replaced by 33 3 450. (0 492 341)

Bush AM

Replaced by: 83300493416

NOTE: (Clamping bush) Discontinuation and replaced by 33 4 400. (0 493 416)

Bush AM

NOTE: Series: E31, E46

Storage Location

C14

Bush AM

NOTE: For accommodating the trailing arm when pressing out

Storage Location

X5

Bush AM

NOTE: (Pressure bushing) For pressing the ball joint into the wishbone

Bush AM

NOTE: For accommodating the engine support arm or wheel carrier when pressing out the ball joint

Storage Location

X5

Bush AM

NOTE: (Pressure bushing) For pressing the ball joint out of the wishbone

Bush AM

NOTE: (Bush (for removal and installation)) Deletion, only available via tool set

Storage Location

C53

SI number

01 18 05 (214)

Bush AM

NOTE: For accommodating the leading link when pressing out

Storage Location

Z8

Bush Mechanical tool

NOTE: (Impact bush) For driving in the radial seal on the drive flange

Storage Location

X7

Bush AM

NOTE: For holding the wishbone when pressing out the rubber mount

Bush Mechanical tool

Replaced by: 83300492339

NOTE: (Impact bush) For fitting the radial sealing rings in the rear axle final drive on the drive flange - Replaced by 33 3 430. (0 492 339)

Bush Mechanical tool

Replaced by: 83300492340

NOTE: (Impact bush) For radial sealing ring on the drive flange without axial sealing lip (final drive type G) and for fitting the radial sealing ring of the camshaft (M40) - Replaced by 33 3 440. (0 492 340)

CASE

Case AM

NOTE: (Case) with label.

CASE

Case Minimum set: Mechanical tools AM

NOTE: (Case) Case with insert discontinued, can only be ordered using complete tool

SI number

01 22 06 (307)

CLIP

Clip Mechanical tool

NOTE: (Mounting bracket) For short neck rear axle differential - model year: from 79

Clip Mechanical tool

NOTE: (Mounting clip) For rear axle differential unit - model: 1800 - 2000CA, 2500 - 3.3L, 525, 3.0CS - 3.0CSi-L

CONNECTOR

Connector AM

NOTE: (Basic body) For transmissions S5D 260Z, S5D 310Z and S5D 320Z;Discontinued, only available via complete tool

Storage Location

Y4

Z4

Device

Device AM

NOTE: For determining the installation size of the bevel drive pinion in the rear axle final drive

Consisting of:

1. Holder

NOTE: (Dial gauge holder)

2. Washer

NOTE: (Measuring disc)

Device AM

NOTE: For determining the installation size of the bevel drive pinion in the rear axle final drive

Consisting of:

1. Holder

NOTE: (Dial gauge holder)

2. Washer

NOTE: (Measuring disc)

Device AM

NOTE: (Pulling device) For pulling out the rubber mount in the final drive

Storage Location

A14

B14

Consisting of:

1. Spindle

NOTE: (Threaded spindle, long) Series: E36/5 sale of existing inventory and then available as part of set of special tools 33 2 120 = 83 30 0 492 179 only - as of 09.12.2011

2. Nut

NOTE: Liquidation of existing inventory and then available only as a complete tool set 33 2 120 = 83 30 0 492 179 - as of 09.12.2011

3. Synchronising key

4. HolderNOTE: (Countersupport) 0496208 =119850

Device AM

NOTE: For determining the installation size of the bevel drive pinion in the rear axle final drive

Consisting of:

1. Holder

NOTE: (Dial gauge holder)

2. Washer

NOTE: (Measuring disc)

Device AM

NOTE: For removing and installing the rubber mount in the 20º trailing arm

Storage Location

B10

C10

Consisting of:

1. Nut

NOTE: (Nut with bearing) Model series: E28, E30, E83

2. Spindle

NOTE: Series: E28, E30, E83

3. Holding sleeve

NOTE: Series: E28, E30 discontinued, available as part of set of special tools only

4. Synchronising key

5. Synchronising key

NOTE: (Synchronising key) Model series: E28, E30 Model: 518 - 735i discontinued, available as part of set of special tools only

6. Synchronising key

NOTE: Series: E28, E30 Model: 316 - 323i discontinued, available as part of set of special tools only

Device AM

NOTE: For removing and installing the ball joint in the wishbone

SI number

01 01 89 (989)

Consisting of:

1. Shaped element

NOTE: For positioning when pressing out the ball joint

2. Bush

NOTE: (Pressure bushing) For pressing the ball joint out of the wishbone

3. Shaped element

NOTE: For positioning the wishbone when pressing in the ball joint

4. Bush

NOTE: (Pressure bushing) For pressing the ball joint into the wishbone

Device Mechanical tool

NOTE: (mounting fixture) For rear axle final drive with modified bore hole - Model: from 83

Device Mechanical tool

NOTE: (Device) For function check of the mechanical limited slip differential

Device AM

NOTE: For determining the side clearance of the differential side gears

Storage Location

Y4

Consisting of:

1. Washer

NOTE: (Washer with thread)

2. Washer

NOTE: (Washer without thread)

Device AM

NOTE: For removing and installing the rubber mount in the trailing arm

SI number

01 01 89 (989)

Consisting of:

1. Holding sleeve

NOTE: (support sleeve) During extraction

2. Holding sleeve

NOTE: (Press-out sleeve)

3. Holding sleeve

NOTE: (Press-in sleeve)

4. Shaped element

NOTE: For pressing in

Device AM

NOTE: For determining the installation size of the bevel drive pinion in the rear axle final drive

Consisting of:

1. Holder

NOTE: (Dial gauge holder)

2. Washer

NOTE: (Measuring disc)

Device AM

NOTE: For removing and installing ball joint in wheel carrier.

Storage Location

C53

SI number

01 18 05 (214)

Consisting of:

1. Synchronising key

NOTE: (Thrust piece (for removing)) Deletion, only available via tool set

2. Bush

NOTE: (Bush (for removal and installation)) Deletion, only available via tool set

3. Synchronising key

NOTE: (Thrust piece (for installing)) Deletion, only available via tool set

Device AM

NOTE: For determining the side clearance of the differential side gears in the differential housing

Storage Location

Z3

Z4

Consisting of:

1. Holder

NOTE: (Dial gauge holder)

2. Adapter

NOTE: (adapter with nut and washer)

3. Extension

NOTE: (extension (2 x))

Device AM

NOTE: For determining the side clearance of the differential side gears

Storage Location

Y3

Consisting of:

1. Screw

2. Washer

Device AM

NOTE: For removing and installing the rubber mount in the wishbone

SI number

01 01 89 (989)

Consisting of:

1. Holding sleeve

NOTE: (Support sleeve) For pressing out

2. Holding sleeve

NOTE: (Press-out sleeve)

3. Holding sleeve

NOTE: (Press-in sleeve)

4. Shaped element

NOTE: For pressing in

Device Mechanical tool

NOTE: For determining the installation dimension of the drive bevel gear in the rear axle differential (also E36/3 and E36/7)

Device AM

NOTE: (Holding device) For fixing the final drive on the assembly stand

SI number

01 05 95 (932)

Consisting of:

1. Frame

NOTE: (Main frame)

2. Screw

NOTE: (Knurled screws (M16 2 x))

Device Mechanical tool

Replaced by: 83300494611

NOTE: For removing the rear axle final drive/Replaced by 33 4 420. (0 494 611)

SI number

01 10 90 (288)

Device AM

NOTE: For determining the installation size of the bevel drive pinion in the rear axle final drive

Consisting of:

1. Holder

NOTE: (Dial gauge holder)

2. Washer

NOTE: (Measuring disc)

Device AM

NOTE: For removing inner wheel bearing races on rear axle

SI number

08 12 14 (155)

Consisting of:

1. Basic body

NOTE: No longer available separately, only available as part of complete tool set 0493416 = 33 4 400.

2. Spindle

NOTE: No longer available separately, only available as part of complete tool set 0493416 = 33 4 400.

3. Wrench

NOTE: (Ignition key) Discontinued, only available via complete tool

4. Wrench

NOTE: (Ignition key) Discontinued, only available via complete tool

5. Pliers

NOTE: (Clamping ring (45 to 51 mm)) No longer available separately, only available as part of complete tool set 0493416 = 33 4 400.

6. Pliers

NOTE: (Clamping ring (50 to 55 mm)) No longer available separately, only available as part of complete tool set 0493416 = 33 4 400.

7. Pliers

NOTE: (clamping ring (55...61 mm)) Model series: E67 No longer available separately, only via complete tool set 0493416 = 33 4 400.

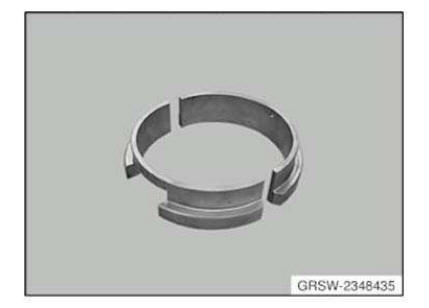

8. Ring

NOTE: (Clamping ring) Model series: F01, F02. Available only as complete special tool set 33 4 400.

9. Synchronising key

NOTE: Series: F01, F02. Remaining inventories will be sold off and then it will no longer be available separately, only available as part of complete tool set 0493416 = 33 4 400.

Device Minimum set: Mechanical tools AM

NOTE: For removing rubber mount in rear axle support.

Storage Location

A8

B8

SI number

01 02 99 (417)

Consisting of:

1. Pipe

NOTE: (Threaded tube) Deletion, only available via tool set

2. Shaped part

NOTE: (Shaped part) 2 pieces Model series: E38, E39, E46 Deletion, only available via tool set

3. Shaped part

NOTE: (Shaped part)

4. Rod

NOTE: (Guide rod)

5. Rod

NOTE: (Guide rod) With thread dog point

6. Plate

NOTE: (Fixing plate) With screws Deletion, only available via tool set

7. Synchronising key

NOTE: (Synchronising key (2 x)) With screws - model series: E38, E39, E46 Deletion, only available via tool set

8. Shaped part

NOTE: (Shaped part) 2 pieces Model series: E39/2, E65, E67, RR1

9. Synchronising key

NOTE: (Synchronising key (2 x)) With countersunk screw - model series: E39/2, E65, E67, E87

Device Minimum set: Mechanical tools AM

NOTE: For removing and installing rubber mount in rear axle final drive at front.

Storage Location

A22

SI number

01 22 06 (307)

Consisting of:

1. Washer

NOTE: Discontinued, can only be ordered using complete tool

2. Holding sleeve

NOTE: Discontinued, can only be ordered using complete tool

3. Washer

NOTE: Discontinued, can only be ordered using complete tool

4. Holding sleeve

NOTE: Discontinued, can only be ordered using complete tool

5. Washer

NOTE: Discontinued, can only be ordered using complete tool

6. Nut

NOTE: (Nut M12x1.5) discontinued, can only be ordered using complete tool

Device AM

NOTE: For removing and installing the rubber mount in the support tube of the rear axle final drive mounting

SI number

01 01 89 (989)

Consisting of:

1. Plate

NOTE: (Shaped plate, top) For removing

2. Plate

NOTE: (Shaped plate, top) For pulling in

3. Plate

NOTE: (Shaped plate, bottom) For pulling in

Device Mechanical tool

Replaced by: 83300492079

NOTE: (Fixture) For all rear axle final drives - model year: From 88 - Replaced by 33 1 070. (0 492 079)

Device AM

NOTE: For pulling off drive flanges (also E46/16).

Storage Location

C17

C18

Consisting of:

3 = Washer

4 = Plate

NOTE: (adapter plate) Transmission: GS6-57DZ, GS6-53BZ (G transmission) GS6- 51DZ, GS6-51BZ (H transmission) Deletion, only available via tool set

5 = Screw

NOTE: (countersunk screws M10x30 (3 x)) Transmission: GS6-57DZ, GS6-53BZ (G transmission) GS6-51DZ, GS6-51BZ (H transmission) Deletion, only available via tool set

1 = Spindle

NOTE: Discontinued, can only be ordered using complete tool

2 = Mandrel

NOTE: Discontinued, can only be ordered using complete tool

Device AM

NOTE: Device A1 in connection with adapter kit 1 (BMW), (81 64 2 155 745), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Device AM

NOTE: For removing and installing outer rings of taper roller bearings

Consisting of:

1 = Shaped part

NOTE: (Shaped part)

2 = Spindle

NOTE: (Spindle, short)

4 = Nut

5 = Washer

NOTE: (Installation washer (2 pieces))

6 = Bridge

NOTE: (Support bridge)

7 = Washer

NOTE: (Thrust washer)

8 = Holding sleeve

NOTE: (Pressure sleeve) Can no longer be ordered separately. Only available as part of set 11 5 330 = 83 30 0 495 127.

Device Minimum set: Mechanical tools AM

NOTE: For removing and installing output shaft in rear axle final drive.

Storage Location

A22

B22

C22

SI number

01 01 07 (333)

Consisting of:

1 = Basic body

NOTE: Only available via complete tool set 33 5 120 - > (83 30 0 495 851).

2 = Screw

NOTE: (Knurled screw with thrust piece) available as part of set of special tools 33 5 120 -> (83 30 0 495 851) only.

3 = Rod

NOTE: Only available via complete tool set 33 5 120 - > (83 30 0 495 851).

4 = Shaped element

NOTE: (Shaped element) shaped element (bearing shell) available as part of set of special tools 33 5 120 -> (83 30 0 495 851) only.

5 = Shaped element

NOTE: Sale of existing inventory then available as part of set of tools 33 5 120 -> (83 30 0 495 851) only.

7 = Shaped part

NOTE: For driving output shaft into rear axle final drive.

6 = Shaped part

NOTE: For pressing output shaft out of rear axle final drive.

In conjunction with: 33 5 120

Extension

Extension Minimum set: Mechanical tools AM

NOTE: (Extension (1 item)) discontinued, can only be ordered using complete tool

SI number

01 21 06 (300)

Extension Minimum set: Mechanical tools AM

NOTE: (2 pieces) Pull-out extension for 33 5 040, 33 5 050, 33 5 060.

Storage Location

A18

B18

SI number

01 21 06 (300)

Consisting of:

1. Extension

NOTE: (Extension (1 item)) discontinued, can only be ordered using complete tool

Extension AM

NOTE: (extension (2 x))

Storage Location

Z3

Extractor AM

NOTE: (Rillex extractor) For bevel pinion and differential case (rear diff)/for installation of camshaft sprocket on crankshaft (M70)/for removing bearing inner race from drive flange (E36, E46)

Storage Location

Y4

Z4

Consisting of:

1 = Connector

NOTE: (Basic body) For transmissions S5D 260Z, S5D 310Z and S5D 320Z;Discontinued, only available via complete tool

2 = Washer

NOTE: (Disc) Replaced by 33 1 311. (0 492 107)

3 = Washer

NOTE: (Disc) Replaced by 33 1 311. (0 492 107)

4 = Washer

NOTE: (Disc) Replaced by 33 1 311. (0 492 107)

5 = Synchronising key

NOTE: (Thrust piece (old)) Discontinued, only available via complete tool

6 = Synchronising key

7 = Synchronising keyNOTE: Not available individually. Only via complete tool set

8 = Synchronising key

9 = Synchronising keyNOTE: For rear axle differential and for installing the camshaft sprocket on the crankshaft (M70) Discontinued, only available via complete tool

1 = Washer

NOTE: (Disc) Discontinued, only available via complete tool

2 = Synchronising key

NOTE: For pulling the bearing inner race off the drive flange - Series: E36/5 Discontinued, only available via complete tool

FITTING AID

Fitting aid Mechanical tool

NOTE: (Installation spoon) For installing the gaiter on the output shafts with sliding joints

Fixture

Fixture AM

NOTE: (Fixture no. 5 and 6)

Fixture AM

NOTE: For holding rear axle final drive during removal and installation. This mounting replaces mounting 33 4 420

SI number

01 01 07 (333)

Consisting of:

1 = Joint

2 = FrameNOTE: (Main frame)

3 = Upholstery

4 = FixtureNOTE: (Fixture for foam material insert) Discontinued, only available via complete tool

5 = Insert

NOTE: (Insert) Foam material insert (1 set = 2 pieces)

5 = Belt

NOTE: (Tensioning strap)

Fixture AM

NOTE: (Fixture no. 5 and 6)

Fixture AM

NOTE: (Fixture for foam material insert) Discontinued, only available via complete tool

SI number

01 01 07 (333)

Fixture AM

NOTE: (Fixture no. 3 and 4)

Fixture AM

NOTE: (Fixture no. 1)

Fixture AM

Replaced by: 83300495567

NOTE: (Mounting set) With gearbox cage for removing and fitting the rear axle.

Replaced by 31 5 250. (0 495 567)

SI number

01 05 90 (207)

Consisting of:

1. Fixture

NOTE: (Fixture no. 1 and 2)

2. Fixture

NOTE: (Fixture no. 3 and 4)

3. Fixture

NOTE: (Fixture no. 5 and 6)

Fixture AM

Replaced by: 83300495567

NOTE: (Mounting set) For removing and installing the rear axle. Replaced by 31 5 250.

(0 495 567)

SI number

01 10 90 (288)

Consisting of:

1. Fixture

NOTE: (Fixture no. 3)

2. Fixture

NOTE: (Fixture no. 1)

3. Fixture

NOTE: (Fixture no. 5 and 6)

NOTE: (Fixture no. 3)

Fixture AM

NOTE: (Fixture no. 1 and 2)

Frame

Frame AM

NOTE: (Main frame)

Frame AM

NOTE: (Main frame)

SI number

01 01 07 (333)

GAUGE

Gauge Mechanical tool

NOTE: (Trailing arm gauge)

GUIDE

Guide Minimum set: Mechanical tools Mechanical tool

NOTE: For pulling out rubber mounts in rear axle support mounting.

Storage Location

C30

SI number

01 22 11 (753)

Holder

Holder AM

NOTE: (Dial gauge holder)

Holder AM

NOTE: (Dial gauge holder)

Holder AM

NOTE: (Dial gauge holder)

Holder Minimum set: Mechanical tools AM

NOTE: (Countersupport) 0496208 =119850

Storage Location

B49

Holder AM

NOTE: (Dial gauge holder)

Storage Location

Z3

Z4

Holder AM

NOTE: (Dial gauge holder)

Holder Minimum set: Mechanical tools AM

NOTE: (Countersupport) 0496208 =119850

Holder Mechanical tool

NOTE: (Counter support) For flange on rear axle shaft

Storage Location

Z7

Holder AM

NOTE: (Dial gauge holder)

Holder AM

NOTE: (Countersupport) 0496208 =119850

Holding sleeve

Holding sleeve Minimum set: Mechanical tools AM

NOTE: Discontinued, can only be ordered using complete tool

Storage Location

B22

SI number

01 01 07 (333)

Holding sleeve AM

NOTE: (Press-in sleeve)

Holding sleeve AM

Holding sleeve Minimum set: Mechanical tools AM

NOTE: For removing and installing rubber mounts and ball joints in rear wheel carriers

Storage Location

C29

C30

SI number

01 22 11 (753)

Holding sleeve Minimum set: Mechanical tools AM

NOTE: (support sleeve)

Holding sleeve AM

NOTE: (Spacer sleeve) For pressing the ball joint into the wheel carrier

Storage Location

X5

Holding sleeve Minimum set: Mechanical tools AM

NOTE: Discontinued, can only be ordered using complete tool

Storage Location

B22

SI number

01 01 07 (333)

Holding sleeve AM

NOTE: (spacer sleeve) For pressing the rubber mount into the differential carrier - Series: E31

Storage Location

C14

Holding sleeve AM

NOTE: (Press-out sleeve)

Holding sleeve AM

NOTE: (support sleeve) During extraction

Holding sleeve Mechanical tool

NOTE: (Assembly sleeve) For fitting the taper roller bearing on the bevel drive pinion

Storage Location

C16

Holding sleeve AM

NOTE: (Press-in sleeve)

Holding sleeve AM

NOTE: Sleeve C1 in connection with adapter kit 1 (BMW), (81 64 2 155 745) and MINI adapter kit (81 64 2 294 517), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Holding sleeve Minimum set: Mechanical tools AM

NOTE: (support sleeve)

Storage Location

B49

Holding sleeve AM

NOTE: (Press-out sleeve)

Holding sleeve AM

NOTE: (Pressure sleeve) Can no longer be ordered separately. Only available as part of set 11 5 330 = 83 30 0 495 127.

Holding sleeve AM

NOTE: (Guide sleeve) to press in the front rubber mount

Storage Location

X5

Holding sleeve AM

NOTE: (Spacer sleeve) For pressing the ball joint into the support arm

Storage Location

X5

Holding sleeve AM

NOTE: Sleeve H1 (removing gear finding component) in connection with adapter kit 1 (BMW), (81 64 2 155 745), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Holding sleeve Mechanical tool

NOTE: For gripping the rear wheel bearing when drawing in the rear axle shaft

Storage Location

X9

Holding sleeve AM

NOTE: (spacer sleeve) For press-fitting the ball joint in the wheel carrier

Storage Location

Z8

Holding sleeve AM

NOTE: (Support sleeve) For pressing out

Holding sleeve AM

NOTE: Sleeve E1 (M24) in connection with adapter kit 1 (BMW), (81 64 2 155 745), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Holding sleeve AM

NOTE: Series: E28, E30 discontinued, available as part of set of special tools only

Holding sleeve AM

NOTE: (Spacer sleeve) for pressing in the rubber mount in the wishbone

Holding sleeve AM

NOTE: (spacer sleeve) For press-fitting the rubber mount into the leading link

Storage Location

Z8

HYDRAULIC

Hydraulic cylinders AM

NOTE: Hydraulic cylinder (hydraulic actuator) in connection with lever, (81 64 2 156 247), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Insert

Insert AM

NOTE: (Insert) Foam material insert (1 set = 2 pieces)

SI number

01 01 07 (333)

Insert AM

NOTE: (Insert) Foam insert, top.

Insert AM

NOTE: (Insert) Foam insert, bottom.

JOINT

Joint AM

SI number

01 01 07 (333)

LEVER

Lever AM

NOTE: Lever in connection with hydraulic cylinder (hydraulic actuator), (81 64 2 156 246), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Mandrel

Mandrel Mechanical tool

NOTE: (Drift) For driving in the retainer on the rear axle shaft

Storage Location

X8

Mandrel Mechanical tool

NOTE: (Guide mandrel) For fitting differential gear shaft into rear axle final drive

Storage Location

X4

Mandrel Mechanical tool

Replaced by: 83300492338

NOTE: (Drift) For radial seal on output flange - Replaced by 33 3 420. (0 492 338)

Mechanical Mandrel Minimum set: Mechanical tools 335080 tool

NOTE: For driving in shaft seal on drive shaft.

Storage Location

A16

SI number

01 21 06 (300)

Mandrel Mechanical tool

NOTE: (Drive-out mandrel) For the rear axle shaft/Replaced by 33 2 116. (0 492 175) and 33 4 200. (0 492 436)

Mandrel Mechanical tool

NOTE: (Drift) For driving in the retainer on the rear axle shaft (wheel bearing) and on the drive flange of the rear axle final drive (final drive types K and M)

Storage Location

A16

SI number

01 03 91 (333)

Mandrel Minimum set: Mechanical tools AM

NOTE: (Drift) For driving radial shaft seal of output shaft into rear axle final drive. Rear axle final drive: 215

Storage Location

B21

C21

SI number

01 01 07 (333)

Mandrel Mechanical tool

NOTE: (Drift) For driving in the radial seal rings in the rear axle final drive at the output flange with flange diameter 35 mm

Storage Location

X7

Mechanical Mandrel Minimum set: Mechanical tools 335130 tool

NOTE: For driving the radial shaft seal of the output shaft into the rear axle final drive.

Rear axle final drive: 188

Storage Location

C21

SI number

01 01 07 (333)

Mandrel Mechanical tool

Replaced by: 83300491891

NOTE: (Drift) Replaced by 31 2 040. (0 491 891)

Mandrel Minimum set: Mechanical tools Mechanical tool

NOTE: (Drift) For driving radial shaft seal onto drive flange. Replaced by 33 3 470/0 496 596

Storage Location

B26

SI number

01 09 09 (532)

Mandrel Mechanical tool

Replaced by: 83300492342

NOTE: (Drift) For driving the radial sealing ring into the output flange, flange diameter 43 mm - Replaced by 33 3 460. (0 492 342)

SI number

01 10 90 (288)

Mandrel Mechanical tool

Replaced by: 83300492338

NOTE: (Drift) For fitting the radial sealing ring, right-hand output end/Replaced by 33 3 420. (0 492 338)

Mandrel Mechanical tool

Replaced by: 83300492339

NOTE: (Drift) For driving the radial seal into the output flange with flange diameter 38 mm - Replaced by 33 3 430. (0 492 339)

Mandrel AM

NOTE: Discontinued, can only be ordered using complete tool

Nut

Nut Minimum set: Mechanical tools AM

NOTE: (Nut TR20)

Nut AM

Nut AM

NOTE: Liquidation of existing inventory and then available only as a complete tool set 33 2 120 = 83 30 0 492 179 - as of 09.12.2011

Nut Minimum set: Mechanical tools AM

NOTE: (Nut M12x1.5) discontinued, can only be ordered using complete tool

Storage Location

B22

SI number

01 01 07 (333)

Nut Minimum set: Mechanical tools AM

NOTE: (Thrust nut)

Nut AM

NOTE: Series: E30, E36

Nut AM

NOTE: (Nut with bearing) Model series: E28, E30, E31, E34, E36, RR1

Storage Location

C13

Nut AM

NOTE: (Nut with bearing) Model series: E28, E30, E83

Nut AM

Nut Minimum set: Mechanical tools AM

NOTE: (nut M12x1.5 (high wall))

SI number

01 16 08 (476)

Nut Minimum set: Mechanical tools AM

NOTE: (nut TR12 with thrust bearing)

Nut Minimum set: Mechanical tools AM

NOTE: (nut TR20 with thrust bearing)

Nut Minimum set: Mechanical tools AM

NOTE: (Nut with thrust piece) discontinued, can only be ordered using complete tool

SI number

01 01 07 (333)

OPEN-END WRENCH

Open-end wrench Mechanical tool

NOTE: (Open-end spanner SW17)

PIPE

Pipe Minimum set: Mechanical tools AM

NOTE: (Threaded tube) Deletion, only available via tool set

Plate

Plate AM

NOTE: (Shaped plate, top) For pulling in

Plate Minimum set: Mechanical tools AM

NOTE: (Fixing plate) With screws Deletion, only available via tool set

Plate AM

NOTE: (Shaped plate, bottom) For pulling in

Plate AM

NOTE: (Shaped plate, top) For removing

Plate AM

NOTE: (adapter plate) Transmission: GS6-57DZ, GS6-53BZ (G transmission) GS6-51DZ, GS6-51BZ (H transmission) Deletion, only available via tool set

Storage Location

C17

SI number

01 11 04 (093)

Pliers

Pliers AM

NOTE: (clamping ring (55...61 mm)) Model series: E67 No longer available separately, only via complete tool set 0493416 = 33 4 400.

Pliers AM

NOTE: (Clamping ring (50 to 55 mm)) No longer available separately, only available as part of complete tool set 0493416 = 33 4 400.

Pliers AM

NOTE: (Clamping ring (45 to 51 mm)) No longer available separately, only available as part of complete tool set 0493416 = 33 4 400.

Ring

Ring AM

NOTE: (pipe) For extracting and press-fitting the rubber mount in the 13º trailing arm

Ring AM

NOTE: (Clamping ring) Model series: F01, F02. Available only as complete special tool set 33 4 400.

SI number

01 18 08 (482)

RING SPANNER

Ring spanner Minimum set: Mechanical tools Mechanical tool

NOTE: Multi-tooth ring spanner SW65 For releasing and tightening down flange nut on rear axle final drive. Only ring spanners with a torque of 700 Nm may be used - as at 02/2014.

Storage Location

A18

SI number

01 21 06 (300)

Ring spanner Mechanical tool

NOTE: (Ring spanner WAF 19) For toe adjustment at the rear axle

Storage Location

X3

SI number

01 07 88 (972)

Ring spanner Minimum set: Mechanical tools AM

NOTE: (Reversible ratchet ring spanner SW24) discontinued, available as part of set of special tools only

SI number

01 01 07 (333)

Rod

Rod Minimum set: Mechanical tools AM

NOTE: (Guide rod) With thread dog point

Rod Minimum set: Mechanical tools AM

NOTE: (Guide rod)

Rod Minimum set: Mechanical tools AM

NOTE: Only available via complete tool set 33 5 120 -> (83 30 0 495 851).

SI number

01 01 07 (333)

Rod Mechanical tool

NOTE: (Split rod) For removing and installing the actuator unit of the active rear axle kinematics

SI number

01 01 92 (469)

Screw

Screw AM

NOTE: (Knurled screws (M16 2 x))

Screw AM

NOTE: (countersunk screws M10x30 (3 x)) Transmission: GS6-57DZ, GS6-53BZ (G transmission) GS6-51DZ, GS6-51BZ (H transmission) Deletion, only available via tool set

Storage Location

C17

SI number

01 11 04 (093)

Minimum set: Mechanical tools AM

NOTE: (Knurled screw with thrust piece) available as part of set of special tools 33 5 120 -> (83 30 0 495 851) only.

SI number

01 01 07 (333)

Screw AM

Screw AM

NOTE: Screws K1 (M12x1.5) for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Screw AM

NOTE: Screws K2 (M14x1.5) for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Shaped element

Shaped element Minimum set: Mechanical tools AM

NOTE: (Shaped element) shaped element (bearing shell) available as part of set of special tools 33 5 120 -> (83 30 0 495 851) only.

SI number

01 01 07 (333)

Shaped element AM

NOTE: For pulling the front rubber mounts out of the rear axle support, series: E36, E46

Storage Location

B13

C13

Shaped element AM

NOTE: For positioning the wishbone when pressing in the ball joint

Shaped element AM

NOTE: For pressing in

Shaped element AM

NOTE: For positioning when pressing out the ball joint

Shaped element AM

NOTE: For pressing in

Shaped element Minimum set: Mechanical tools Mechanical tool

NOTE: For pulling out rubber mounts in rear axle support mounting.

Storage Location

C29

SI number

01 22 11 (753)

Shaped element AM

NOTE: For pulling the rear rubber mounts out of the rear axle support, series: E36, E46

Storage Location

B13

Shaped element Minimum set: Mechanical tools AM

NOTE: Sale of existing inventory then available as part of set of tools 33 5 120 -> (83 30 0 495 851) only.

SI number

01 01 07 (333)

Shaped part

Shaped part AM

NOTE: (Shaped part)

Storage Location

Y8

SHAPED

Shaped part AM

NOTE: For removing the wheel bearing inner race from the drive flange hub in combination with special tool 33 4 400 and hydraulic tool 81 64 2 160 009.

Storage Location

C29

C30

SI number

01 15 11 (737)

SHAPED PART

Shaped part Minimum set: Mechanical tools AM

In conjunction with: 33 5 120 = 0495851

NOTE: For pressing output shaft out of rear axle final drive.

SI number

01 28 09 (600)

Shaped part Minimum set: Mechanical tools AM

NOTE: For driving output shaft into rear axle final drive.

SI number

01 28 09 (600)

Shaped part AM

NOTE: (Shaped part)

Shaped part Minimum set: Mechanical tools AM

NOTE: (Shaped part) 2 pieces Model series: E38, E39, E46 Deletion, only available via tool set

Storage Location

B8

Shaped part Minimum set: Mechanical tools AM

NOTE: (Shaped part)

Shaped part Minimum set: Mechanical tools AM

NOTE: (Shaped part) 2 pieces Model series: E39/2, E65, E67, RR1

Shell

Shell AM

Replaced by: 83300493416

NOTE: (Shell) Model series: E31, E38 Discontinuation and replaced by 33 4 400. (0 493 416)

Shell AM

Replaced by: 83300493416

NOTE: Discontinuation and replaced by 33 4 400 (0 493 416)

Shell AM

Replaced by: 83300493416

NOTE: (Shell) Model series: E31, E38 Discontinuation and replaced by 33 4 400. (0 493 416)

Shell AM

NOTE: (Bearing shell)

SOCKET NUT

Socket nut Minimum set: Mechanical tools Mechanical tool

NOTE: (Socket nut) z34 For holding the gearbox input shaft when releasing and tightening down flange nut.

Storage Location

A18

SI number

01 21 06 (300)

Socket wrench

Socket wrench AM

NOTE: (Socket wrench)

Socket wrench Minimum set: Mechanical tools AM

NOTE: (Socket wrench, hex socket, 6 mm) discontinued, available as part of set of special tools only

Socket wrench Minimum set: Mechanical tools AM

NOTE: (Socket wrench SW18) discontinued, available as part of set of special tools only

Socket wrench Minimum set: Mechanical tools AM

NOTE: (Socket wrench SW18) For releasing and tightening down support bearing screw connection.

Storage Location

A25

SI number

01 18 08 (482)

Consisting of:

1. Socket wrench

NOTE: (Socket wrench SW18) discontinued, available as part of set of special tools only

2. Socket wrench

NOTE: (Socket wrench, hex socket, 6 mm) discontinued, available as part of set of special tools only

Spindle

Spindle AM

NOTE: Discontinued, can only be ordered using complete tool

Spindle AM

NOTE: Spindle F3 (M24/270mm) in connection with adapter kit 1 (BMW), (81 64 2 155 745) and MINI adapter kit (81 64 2 294 517) for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Spindle AM

NOTE: For installing - model series: E28, E30, E31, E36

Storage Location

C13

Spindle Minimum set: Mechanical tools AM

NOTE: (spindle TR20 (length 300 mm))

Spindle AM

NOTE: (Threaded spindle, long) Series: E36/5 sale of existing inventory and then available as part of set of special tools 33 2 120 = 83 30 0 492 179 only - as of 09.12.2011

SI number

01 01 94 (766)

Spindle AM

NOTE: No longer available separately, only available as part of complete tool set 0493416 = 33 4 400.

Spindle AM

NOTE: Spindle F2 (M20/M24/355mm) in connection with adapter kit 1 (BMW), (81 64 2 155 745), and MINI adapter kit, (81 64 2 294 517), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Spindle AM

NOTE: (Spindle for installation) Model series: E28, E30, E31, E36, RR1

Storage Location

C13

Spindle AM

NOTE: Series: E28, E30, E83

Spindle Minimum set: Mechanical tools AM

NOTE: (spindle 205 mm, M12)

Spindle Minimum set: Mechanical tools AM

NOTE: Discontinued, can only be ordered using complete tool

SI number

01 01 07 (333)

Spindle AM

Spindle AM

NOTE: For removing and installing front/rear rubber mounts in rear axle support

Storage Location

B13

SI number

01 10 90 (288)

Consisting of:

1. Shaped element

NOTE: For pulling the rear rubber mounts out of the rear axle support, series: E36, E46

2. Washer

NOTE: (Thrust washer) For installing the front/rear rubber mount, series: E36, E46

3. Shaped element

NOTE: For pulling the front rubber mounts out of the rear axle support, series: E36, E46

4. Spindle

NOTE: For pulling out the front rubber mount, series: E36, E46

Spindle AM

NOTE: (Spindle, short)

Spindle AM

Replaced by: 83300493416

NOTE: Discontinuation and replaced by 33 4 400. (0 493 416)

Spindle Minimum set: Mechanical tools AM

NOTE: (spindle TR12)

SI number

01 16 08 (476)

Spindle Minimum set: Mechanical tools AM

In conjunction with: 33 4 030, 33 4 040 = 0492359

NOTE: (spindle TR20 with nut)

SI number

01 16 08 (476)

Consisting of

1. Spindle

NOTE: (spindle TR20 (length 300 mm))

2. Nut

NOTE: (nut TR20 with thrust bearing)

3. Nut

NOTE: (Nut TR20)

Spindle AM

NOTE: Spindle F1 (M24/425 mm) in connection with adapter kit 1 (BMW), (81 64 2 155 745), for removal and installation of wheel bearings, propeller shafts drive flanges.

SI number

08 06 09 (544)

Spindle AM

Replaced by: 83300492222

NOTE: Replaced by 33 3 107. (0 492 222)

Spindle Minimum set: Mechanical tools AM

NOTE: (spindle TR12 with nut)

SI number

01 16 08 (476)

Consisting of:

1. Spindle

NOTE: (spindle TR12)

2. Nut

NOTE: (nut TR12 with thrust bearing)

3. Nut

NOTE: (nut M12x1.5 (high wall))

Spindle AM

Spindle AM

NOTE: For pulling out the front rubber mount, series: E36, E46

Storage Location

B13

C13

Spindle AM

NOTE: (Spindle with pressure pad)

Spring cups

Spring cups AM

NOTE: (spring cup, top)

Spring cups Minimum set: Mechanical tools AM

NOTE: Discontinued, can only be ordered using complete tool

SI number

01 01 07 (333)

Spring cups AM

NOTE: (spring cup, bottom)

Spring cups Minimum set: Mechanical tools AM

NOTE: Discontinued, can only be ordered using complete tool

SI number

01 01 07 (333)

Spring tensioner

Spring tensioner AM

NOTE: For tensioning coil springs when removing and installing coil springs and/or shock absorbers

SI number

01 05 90 (207)

Consisting of:

1. Spring cups

NOTE: (spring cup, top)

2. Spring cups

NOTE: (spring cup, bottom)

3. Synchronising key

NOTE: (synchronising key, complete)

4. Spindle

5. Nut

6. Socket wrenchNOTE: (Socket wrench)

Spring tensioner Minimum set: Mechanical tools AM

NOTE: For tensioning or removing and installing barrel spring on rear axle.

SI number

01 01 07 (333)

Consisting of:

1. Spring cups

NOTE: Discontinued, can only be ordered using complete tool

2. Spring cups

NOTE: Discontinued, can only be ordered using complete tool

3. Spindle

NOTE: Discontinued, can only be ordered using complete tool

4. Nut

NOTE: (Nut with thrust piece) discontinued, can only be ordered using complete tool

5. Ring spanner

NOTE: (Reversible ratchet ring spanner SW24) discontinued, available as part of set of special tools only

6. Case

NOTE: (Case) Case with insert discontinued, can only be ordered using complete tool

Synchronising key

Synchronising key AM

Storage Location

Y4

Synchronising key AM

NOTE: For ball bearing, inner

Synchronising key AM

Synchronising key AM

NOTE: (Thrust piece (for removing)) Deletion, only available via tool set

Storage Location

C53

SI number

01 18 05 (214)

Synchronising key AM

NOTE: For pressing the rubber mount out of the rear axle final drive mounting Series: E31

Storage Location

C14

Synchronising key AM

NOTE: (thrust piece and pipe) For extracting and press-fitting the rotation slide bearing and rubber mount in the 13º trailing arm

Storage Location

X10

Consisting of:

1. Synchronising key

NOTE: For removing and installing the rotary slide mount in the 13º trailing arm/Series: E34, E32/Model: M5, 750i

2. Ring

NOTE: (pipe) For extracting and press-fitting the rubber mount in the 13º trailing arm

Synchronising key AM

NOTE: For pressing the ball joint out of the engine support arm or wheel carrier

Storage Location

X5

Synchronising key Minimum set: Mechanical tools AM

NOTE: (Synchronising key (2 x)) With countersunk screw - model series: E39/2, E65, E67, E87

SI number

01 15 04 (117)

Synchronising key AM

NOTE: Series: F01, F02. Remaining inventories will be sold off and then it will no longer be available separately, only available as part of complete tool set 0493416 = 33 4 400.

Synchronising key AM

NOTE: Series: E28, E30 Model: 316 - 323i discontinued, available as part of set of special tools only

Synchronising key AM

NOTE: For pressing out the front rubber mount

Storage Location

X5

Synchronising key AM

NOTE: For removing and installing the rotary slide mount in the 13º trailing arm/Series: E34, E32/Model: M5, 750i

Synchronising key Mechanical tool

NOTE: For removing rubber mount in rear axle support (E46/5)

SI number

01 12 01 (743)

Synchronising key AM

Replaced by: 83300493416

NOTE: (Synchronising key) Model series: E38, E39 Discontinuation and replaced by 33 4 400. (0 493 416)

Synchronising key AM

Storage Location

Y4

Synchronising key AM

Synchronising key AM

NOTE: For pressing out the rubber mount from the wishbone

Synchronising key AM

NOTE: (synchronising key, complete)

Synchronising key Minimum set: Mechanical tools AM

NOTE: (Synchronising key (2 x)) With screws - model series: E38, E39, E46 Deletion, only available via tool set

Storage Location

B8

Synchronising key AM

NOTE: (Thrust piece (for installing)) Deletion, only available via tool set

Storage Location

C53

SI number

01 18 05 (214)

Synchronising key AM

NOTE: For pressing the rubber mount out of the leading link

Storage Location

Z8

Synchronising key AM

NOTE: (Synchronising key) Model series: E28, E30 Model: 518 - 735i discontinued, available as part of set of special tools only

Synchronising key AM

NOTE: Not available individually. Only via complete tool set

Storage Location

Y4

Synchronising key AM

NOTE: For pulling the bearing inner race off the drive flange - Series: E36/5 Discontinued, only available via complete tool

Storage Location

Y4

SI number

01 01 94 (766)

Synchronising key AM

NOTE: For ball bearing, outer

Synchronising key AM

NOTE: (Thrust piece (old)) Discontinued, only available via complete tool

Storage Location

Y4

Synchronising key Mechanical tool

NOTE: For removing and installing the rubber mounts in the 13º trailing arm

Storage Location

X10

Synchronising key AM

NOTE: For rear axle differential and for installing the camshaft sprocket on the crankshaft (M70) Discontinued, only available via complete tool

Storage Location

Y4

TENSIONING STRAP

Tensioning strap Mechanical tool

NOTE: For removing and installing the pressure accumulator for the hydraulic unit of the rear axle differential lock

Storage Location

X10

Y10

SI number

01 07 92 (516)

Tool

Tool AM

NOTE: (Set of pressing-in/pressing-out tools) Form pressing in and pressing out the ball joint position in the supporting arm and wheel carrier

Storage Location

X5

SI number

01 05 90 (207)

Consisting of:

1 = Bush

NOTE: For accommodating the engine support arm or wheel carrier when pressing out the ball joint

2 = Synchronising key

NOTE: For pressing the ball joint out of the engine support arm or wheel carrier

3 = Holding sleeve

NOTE: (Spacer sleeve) For pressing the ball joint into the support arm

3 = Holding sleeve

NOTE: (Spacer sleeve) For pressing the ball joint into the wheel carrier

Tool AM

Replaced by: 83300493416

NOTE: For removing the bearing shell on the rear axle shaft. Replaced by 33 4 400. (0 493 416)

Storage Location

Y5

Consisting of:

1. Shell

NOTE: (Bearing shell)

2. Shell

NOTE: Discontinuation and replaced by 33 4 400 (0 493 416)

3. Holding sleeve

4. Spindle

Tool AM

NOTE: For removing and installing rubber mount in rear axle support

Storage Location

A14

Consisting of:

1 = Washer

NOTE: (Shaped washer) For pulling out the top rubber mount Series: E30, E36

2 = Washer

NOTE: (Shaped washer) For installing the bottom rubber mount Series: E30, E36

3 = Washer

NOTE: (Form disc) Replaced by 33 3 115. (0 492 227)

5 = Washer

NOTE: (Shaped washer) For gripping when installing

4 = Nut

NOTE: Series: E30, E36

Tool Mechanical tool

NOTE: For pulling off drive flanges

Tool AM

NOTE: (extraction/press-fit tool set) For extracting and press-fitting the rubber mounts into the leading link

Storage Location

Z8

SI number

01 05 90 (207)

Consisting of:

1. Bush

NOTE: For accommodating the leading link when pressing out

2. Synchronising key

NOTE: For pressing the rubber mount out of the leading link

3. Holding sleeve

NOTE: (spacer sleeve) For press-fitting the rubber mount into the leading link

4. Holding sleeve

NOTE: (spacer sleeve) For press-fitting the ball joint in the wheel carrier

Tool AM

NOTE: To pull in the wheel bearings and radial seals on the rear axle - model year: up to 82 (E23, E24)

Consisting of:

1. Synchronising key

NOTE: For ball bearing, outer

2. Synchronising key

NOTE: For ball bearing, inner

Tool Minimum set: Mechanical tools AM

NOTE: For removing and installing camber arm rubber mount on rear axle support.

Storage Location

B49

C49

SI number

01 15 04 (117)

Consisting of:

1. Washer

NOTE: (draw-in disc)

2. Washer

NOTE: (pull-out disc)

3. Holder

NOTE: (Countersupport) 0496208 =119850

4. Holding sleeve

NOTE: (support sleeve)

5. Spindle

NOTE: (spindle 205 mm, M12)

6. Nut

NOTE: (Thrust nut)

Tool AM

NOTE: (Extraction tool and press-in tool set) for extracting and pressing in the rubber mount in the wishbone/rubber mount in the wishbone not available separately as replacement part

SI number

01 05 90 (207)

Consisting of:

1. Bush

NOTE: For holding the wishbone when pressing out the rubber mount

2. Synchronising key

NOTE: For pressing out the rubber mount from the wishbone

3. Holding sleeve

NOTE: (Spacer sleeve) for pressing in the rubber mount in the wishbone

Tool AM

NOTE: (Pressing-in/out tool set) for removing and installing the rubber mount on the front trailing arm

Storage Location

X5

SI number

01 05 90 (207)

Consisting of:

1. Bush

NOTE: For accommodating the trailing arm when pressing out

2. Synchronising key

NOTE: For pressing out the front rubber mount

3. Holding sleeve

NOTE: (Guide sleeve) to press in the front rubber mount

Tool AM

NOTE: (extractor/press-fit tool set) For extracting and press-fitting the rubber mount in the differential carrier

Storage Location

C14

SI number

01 05 90 (207)

Consisting of:

1. Bush

NOTE: Series: E31, E46

2. Synchronising key

NOTE: For pressing the rubber mount out of the rear axle final drive mounting Series: E31

3. Holding sleeve

NOTE: (spacer sleeve) For pressing the rubber mount into the differential carrier - Series: E31

Tool AM

NOTE: (Tool set) For removing and installing rubber mounts in rear axle support

Storage Location

C13

Consisting of:

1. Spindle

NOTE: Replaced by 33 3 107. (0 492 222)

2. Washer

NOTE: (Shaped washer) For removing - model series: E28

3. Spindle

NOTE: (Spindle for installation) Model series: E28, E30, E31, E36, RR1

4. Nut

NOTE: (Nut with bearing) Model series: E28, E30, E31, E34, E36, RR1

5. Washer

NOTE: (Shaped washer) For installing - model series: E28

6. Washer

NOTE: (Shape washer) For counter support during installing - model series: E28

7. Spindle

NOTE: For installing - model series: E28, E30, E31, E36

Tool AM

Replaced by: 83300493416

NOTE: (Tool set) For removing bearing inner race from drive flange (rear wheel bearing) - Replaced by 33 4 400. (0 493 416)

Storage Location

C28

SI number

01 05 90 (207)

Consisting of:

1. Shell

NOTE: (Shell) Model series: E31, E38 Discontinuation and replaced by 33 4 400. (0 493 416)

2. Shell

NOTE: (Shell) Model series: E31, E38 Discontinuation and replaced by 33 4 400. (0 493 416)

3. Bush

NOTE: (Clamping bush) Discontinuation and replaced by 33 4 400. (0 493 416)

4. Spindle

NOTE: Discontinuation and replaced by 33 4 400. (0 493 416)

5. Synchronising key

NOTE: (Synchronising key) Model series: E38, E39 Discontinuation and replaced by 33 4 400. (0 493 416)

Tool AM

NOTE: (tool set) For removing and fitting the rubber mounts in the rear axle support, lateral

Storage Location

Y9

SI number

01 04 88 (566)

Consisting of:

1. Washer

NOTE: (Extractor disc) sale of existing inventory and then available as part of complete tool set 33 3 120 = 83 30 0 492 228 only - as of 29.11.2011

2. Washer

NOTE: (Installation disc) Liquidation of existing inventory and then available only via complete tool set 33 3 120 = 83 30 0 492 228 - status 29.11.2011

3. Washer

NOTE: For counter support when pulling in Only available via complete tool set 33 3 120 = 83 30 0 492 228 - status 29.11.2011

Tool AM

Replaced by: 83300492436

NOTE: (Tool set) For pulling out rear drive flange from wheel bearing - replaced by 33 4 200. (0 492 436)

Consisting of:

1. Spindle

NOTE: (Spindle with pressure pad)

2. Basic unit

NOTE: Discontinuation and replaced by 33 4 200. (0 492 436)

Tool Mechanical tool

NOTE: To pull off of ball bearings from the drive shaft (pinion head) - discontinued on 18.01.95

Tool AM

NOTE: (Tool supplement) For 33 1 350, 33 1 360, 33 1 356, 33 1 362, 33 1 363 and 33 1 358

Storage Location

Y8

Consisting of:

1. Shaped part

NOTE: (Shaped part)

2. Washer

NOTE: (Thrust washer)

3. Washer

NOTE: (Installation washer) For bearing shell (engine on inside)

4. Washer

NOTE: (Installation disc) for bearing shell (outside drive) discontinued, available as part of set of special tools only

Tool Minimum set: Mechanical tools AM

NOTE: (tool set) For removing and installing trailing arm rubber mount on rear axle support.

Storage Location

B49

SI number

01 15 04 (117)

Consisting of:

1. Washer

NOTE: (draw-in disc)

2. Washer

NOTE: (pull-out disc)

3. Washer

NOTE: (draw-in disc)

4. Holding sleeve

NOTE: (support sleeve)

5. Holder

NOTE: (Countersupport) 0496208 =119850

Tool AM

NOTE: (Tool set) Complete tool set in a case, for removing and installing the rubber mounts in the rear axle support. The case contains the following special tools: - 33 3 314/315 - 33 3 370 - 33 4 140 - 33 4 150 - 33 4 210

SI number

01 19 03 (017)

Consisting of:

1. Case

NOTE: (Case) with label.

2. Insert

NOTE: (Insert) Foam insert, bottom.

3. Insert

NOTE: (Insert) Foam insert, top.

Tool set AM

NOTE: Threaded spindle set for removing and installing the rubber mount on the rear axle support.

SI number

08 06 10 (658)

Consisting of:

4 = 2208574

3 = 2208575

2 = 2208576

1 = 2208577

Tool set AM

NOTE: Adapter kit 2 (BMW), (BMW-specific adapters), for installation and removal of wheel bearings, propeller shafts and drive shafts.

SI number

08 12 14 (155)

Consisting of:

1 = 2159721

14 = 2159722

18 = 2156282

17 = 2156283

2 = 2159723

16 = 2156275

15 = 2156273

13 = 2156280

12 = 2156279

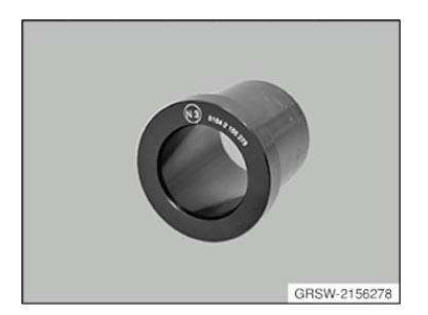

11 = 2156278

10 = 2156277

3 = 2156285

4 = 2159724

5 = 2156289

6 = 2156288

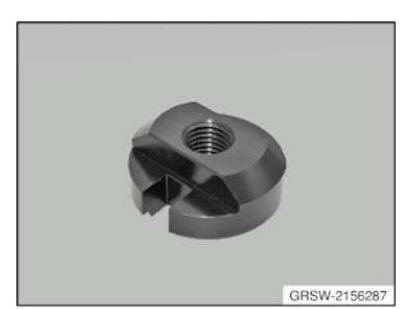

7 = 2156287

8 = 2156286

9 = 2156284

Tool set AM

NOTE: A set of the BMW hydraulic tool system for wheel bearings and output shafts (basic set for BMW, consisting of 81 64 2 155 744, 81 64 2 155 745, 81 64 2 155 746)

SI number

08 12 14 (155)

Tool set AM

NOTE: Hydraulic unit (basic unit) for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 12 14 (155)

Consisting of:

2 = 2156247

1 = 2156246

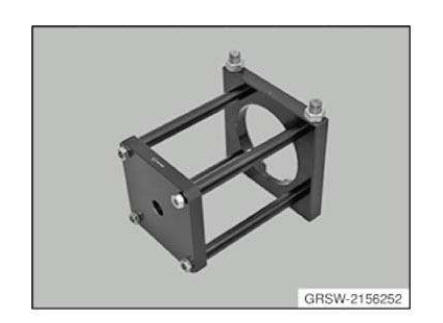

Tool set AM

NOTE: Wheel bearing adapter kit 1 (BMW), (spindles and tensioning nuts) for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 12 14 (155)

Consisting of:

15 = 2156262

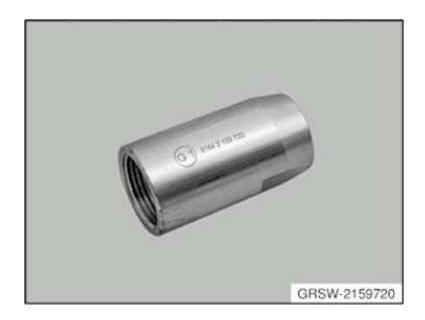

14 = 2159720

13 = 2156257

12 = 2156256

11 = 2318476

10 = 2159986

9 = 2159985

1 = 2156252

2 = 2156253

3 = 2156254

4 = 2156255

5 = 2156258

6 = 2156260

7 = 2156265

8 = 2156271

16 = 2156270

UPHOLSTERY

Upholstery AM

SI number

01 01 07 (333)

Washer

Washer Minimum set: Mechanical tools AM

NOTE: For installing ball joint in rear wheel carrier (bottom camber control arm)

Storage Location

C30

SI number

01 22 11 (753)

Washer AM

NOTE: For counter support when pulling in Only available via complete tool set 33 3 120 = 83 30 0 492 228 - status 29.11.2011

Washer Minimum set: Mechanical tools Mechanical tool

Replaced by: 83300494797

NOTE: (Shim) For removing and installing output shaft in drive flange, front and rear, as well as for removing front wheel bearing unit. Replaced by 33 2 160 (0 494 797)

SI number

01 15 99 (483)

Washer Minimum set: Mechanical tools Mechanical tool

NOTE: For installing rubber mount in rear wheel carrier (bottom trailing arm).

Storage Location

C30

SI number

01 22 11 (753)

Washer AM

NOTE: (Measuring disc)

Washer AM

NOTE: (Measuring disc)

Washer Minimum set: Mechanical tools AM

NOTE: (draw-in disc)

Storage Location

B49

Washer Minimum set: Mechanical tools AM

NOTE: (pull-out disc)

NOTE: (Installation disc) Liquidation of existing inventory and then available only via complete tool set 33 3 120 = 83 30 0 492 228 - status 29.11.2011

Washer AM

NOTE: (Installation washer) For bearing shell (engine on inside)

Storage Location

Y8

Washer AM

NOTE: (Shape washer) For counter support during installing - model series: E28

Storage Location

C13

Washer Minimum set: Mechanical tools AM

NOTE: Discontinued, can only be ordered using complete tool

Storage Location

B22

SI number

01 01 07 (333)

Washer AM

NOTE: (Shaped washer) For gripping when installing

Washer AM

NOTE: (Washer without thread)

Washer AM

NOTE: (Shaped washer) For removing - model series: E28

Storage Location

C13

Washer AM

NOTE: (Installation washer (2 pieces))

Washer AM

NOTE: Contact disc D1 in connection with adapter kit 1 (BMW), (81 64 2 155 745) and MINI adapter kit (81 64 2 294 517), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Washer AM

NOTE: (Disc) Discontinued, only available via complete tool

Storage Location

Y4

Z4

Washer AM

NOTE: (Extractor disc) sale of existing inventory and then available as part of complete tool set 33 3 120 = 83 30 0 492 228 only - as of 29.11.2011

Washer AM

NOTE: (Thrust washer)

Storage Location

Y8

Washer AM

Replaced by: 83300492107

NOTE: (Disc) Replaced by 33 1 311. (0 492 107)

Washer AM

NOTE: (Thrust washer) For installing the front/rear rubber mount, series: E36, E46

Storage Location

B13

Washer Minimum set: Mechanical tools Mechanical tool

NOTE: For removing ball joint in rear wheel carrier (bottom camber arm).

Storage Location

C29

SI number

01 22 11 (753)

Washer AM

NOTE: (Shaped washer) For installing - model series: E28

Storage Location

C13

Washer AM

Replaced by: 83300492107

NOTE: (Disc) Replaced by 33 1 311. (0 492 107)

Washer Minimum set: Mechanical tools Mechanical tool

NOTE: For installing rubber mounts in rear axle support mounting.

Storage Location

C29

SI number

01 22 11 (753)

Washer Minimum set: Mechanical tools AM

NOTE: (pull-out disc)

Storage Location

B49

Washer Minimum set: Mechanical tools AM

NOTE: Discontinued, can only be ordered using complete tool

Storage Location

A22

SI number

01 01 07 (333)

Washer Minimum set: Mechanical tools AM

NOTE: Discontinued, can only be ordered using complete tool

Storage Location

A22

SI number

01 22 06 (307)

Washer Minimum set: Mechanical tools AM

NOTE: (draw-in disc)

Washer Mechanical tool

NOTE: For driving in the radial shaft seal on the input flange

Washer AM

NOTE: (Shaped washer) For pulling out the top rubber mount Series: E30, E36

Washer Minimum set: Mechanical tools Mechanical tool

NOTE: For installing rubber mounts in rear axle support mounting.

Storage Location

C29

SI number

01 22 11 (753)

Washer AM

NOTE: (Measuring disc)

Washer AM

NOTE: Contact disc (M24) E3 in connection with adapter kit 1 (BMW), (81 64 2 155 745) and MINI adapter kit (81 64 2 294 517), for removal and installation of wheel bearings, propeller shafts and drive flanges.

SI number

08 06 09 (544)

Washer AM

NOTE: (Installation disc) for bearing shell (outside drive) discontinued, available as part of set of special tools only

Storage Location

Y8

Washer AM

Washer AM

Washer AM

NOTE: (Measuring disc)

Washer Minimum set: Mechanical tools AM

NOTE: For removing rubber mounts in rear wheel carrier (top wishbone and bottom trailing arm)

Storage Location

C30

SI number

01 22 11 (753)

Washer Minimum set: Mechanical tools AM

NOTE: (draw-in disc)

Storage Location

B49

Washer Minimum set: Mechanical tools AM

NOTE: For installing rubber mount in rear wheel carrier (top wishbone).

Storage Location

C29

SI number

01 22 11 (753)

Washer AM

NOTE: (Shaped washer) For installing the bottom rubber mount Series: E30, E36

Washer AM

Replaced by: 83300492107

NOTE: (Disc) Replaced by 33 1 311. (0 492 107)

Washer AM

NOTE: (Thrust washer)

Washer AM

NOTE: (Washer with thread)

Washer AM

NOTE: (Measuring disc)

Washer Mechanical tool

NOTE: (Shaped disc) For pulling the rubber mount out of the front trailing arm

Storage Location

A14

SI number

01 10 90 (288)

Washer AM

Replaced by: 83300492227

NOTE: (Form disc) Replaced by 33 3 115. (0 492 227)

Wrench

Wrench AM

NOTE: (Ignition key) Discontinued, only available via complete tool

Wrench Minimum set: Mechanical tools AM

In conjunction with: 33 5 070 = 0495554

NOTE: For loosening and tightening the propeller shaft to rear axle final drive screw connection (slot nut). SW50. Replaces SWZ 33 5 040 (0495551) as well from 09/2014.

Storage Location

B28

SI number

01 11 10 (641)

Wrench AM

NOTE: (Ignition key) Discontinued, only available via complete tool

GENERAL - TRACK WIDTH

GENERAL - TRACK WIDTH SPECIFICATION

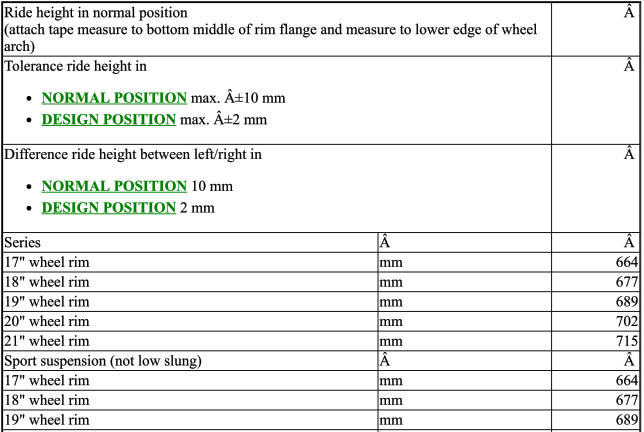

TED-TED-TDMUC3300-F25_HOEHEB1S1 REAR AXLE - RIDE HEIGHT, BMW, F25

REAR AXLE - RIDE HEIGHT F25

REAR AXLE - RIDE HEIGHT SPECIFICATION

REAR AXLE FINAL DRIVE, 188LW

REAR AXLE FINAL DRIVE SPECIFICATION

REAR AXLE FINAL DRIVE, 215LW

REAR AXLE FINAL DRIVE SPECIFICATION

ANTI-ROLL BAR

TIGHTENING TORQUE SPECIFICATION - ANTI-ROLL BAR

REAR AXLE SUSPENSION

TIGHTENING TORQUE SPECIFICATION - REAR AXLE SUSPENSION

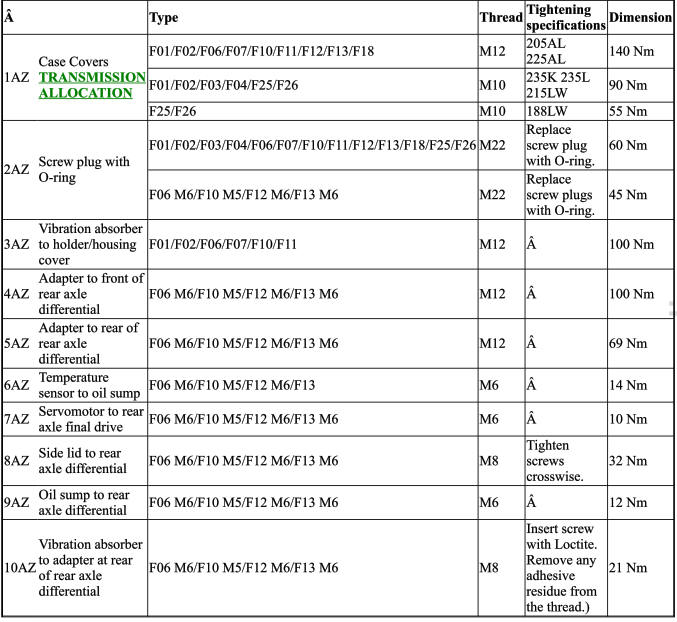

REAR DIFFERENTIAL CASE WITH COVER

TIGHTENING TORQUE SPECIFICATION - REAR DIFFERENTIAL CASE WITH COVER

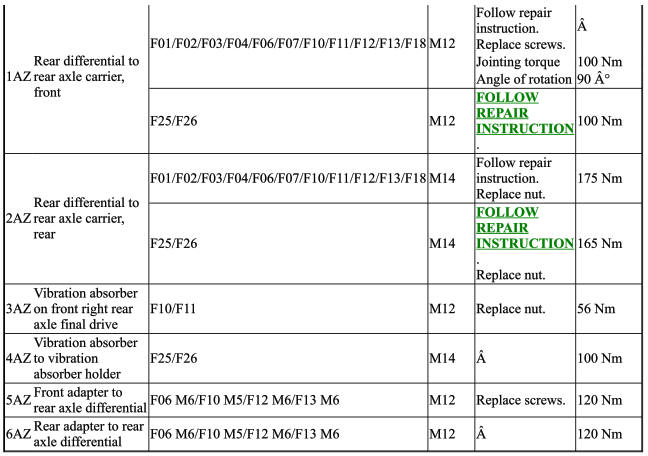

REAR AXLE DIFFERENTIAL MOUNTINGS

TIGHTENING TORQUE SPECIFICATION - REAR AXLE DIFFERENTIAL MOUNTINGS

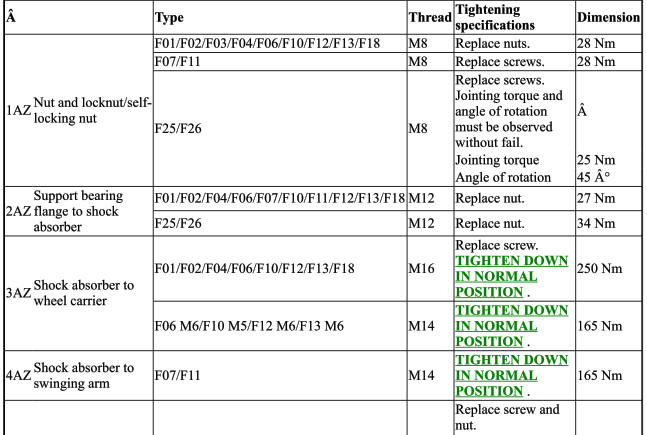

SHOCK ABSORBERS

TIGHTENING TORQUE SPECIFICATION - SHOCK ABSORBERS

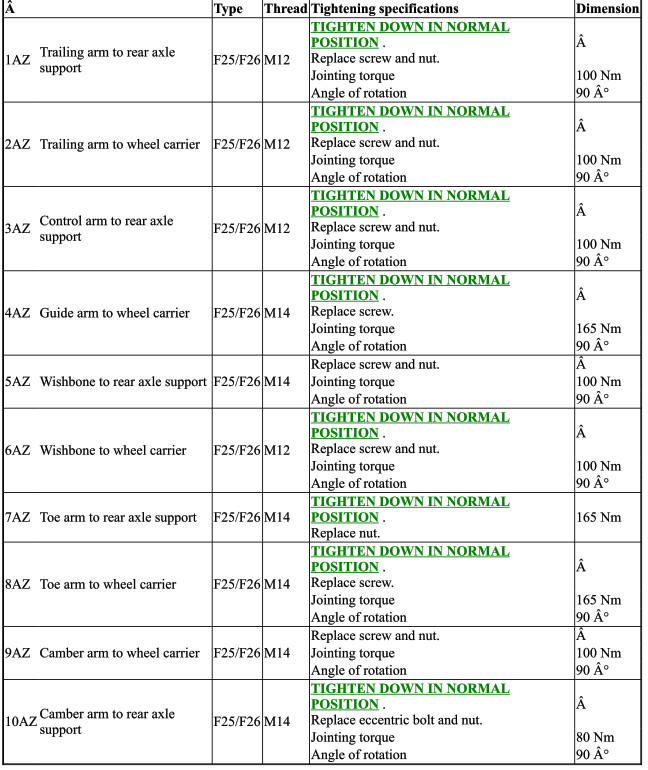

TRAILING ARMS AND STRUTS

TIGHTENING TORQUE SPECIFICATION - TRAILING ARMS AND STRUTS

WHEEL BEARINGS

TIGHTENING TORQUE SPECIFICATION - WHEEL BEARINGS

Stabilizer bar

Stabilizer bar

...

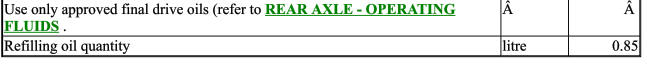

General information on final drive oil

General information on final drive oil

1.0 GENERAL INFORMATION ON FINAL DRIVE OIL

Final Drive oil or hypoid gear lubricant must conform with the following requirements because of the hig ...

Other materials:

BMW X3 (F25) Service & Repair Manual > Driveline+Axles: With suspension

REMOVING AND INSTALLING/REPLACING REAR LEFT OR RIGHT COIL SPRING

Installation note:

1. All screws, nuts, bolts and hose clamps removed during the repair must be replaced.

2. Retaining elements on chassis and suspension and steering parts must be replaced.

IMPORTANT:

Both coil sp ...