BMW X3 (F25) Service & Repair Manual: Body repair instructions

- Contents of body, general

- Blind rivet

- Bonding on painted/primed surfaces

- Bonding steel on steel

- Checklist for front seat

- Corrosion protection

- Emc screws

- Frame alignment control dimensions, body

- Gap dimensions, body

- General instructions on paintwork

- General notes for labelling with adhesive films

- Grinding aluminum components

- Grinding steel parts

- Handling airbags and restraint systems

- Handling electrical system and electronics

- Information on hazards

- Information on metal filler

- Information on using cleaning agent/paints (personal protection equipment)

- Information on vehicle protection

- Installation solution for straight shank/hexagon rivet nut

- Installing a cavity sealing with 2-component pu cavity foam

- Installing cavity sealing (expanded)

- Installing cavity sealing (not expanded)

- Materials science

- Notes for repairing aluminum rims

- Notes on adhesive K1

- Notes on adhesive K2

- Notes on adhesive K3

- Notes on adhesive K4

- Notes on adhesive K5

- Notes on adhesive K6

- Notes on handling the high pressure cleaner

- Notes on repairing threads

- Notes on the water drain hose of the slide/tilt sunroof

- Notes on using temperature-controlled infra-red radiators

- Opening bonded connections

- Opening rivet connections

- Opening welded connections

- Overview of adhesive cartridge guns

- Position of shaped parts for cavity sealing

- Punch rivets

- Quality standard

- Reinforcement plate (bonded)

- Reinforcement plate with stud bolt (bonded)

- Releasing bonded folded seam connections

- Repair methods, repair stages 1

- Repair solution for straight shank/hexagon rivet nut

- Repair techniques, repair stage 2

- Repair techniques, repair stage 3

- Repairing clips for roof strip

- Repairing headlights

- Repairing plastic components

- Replacement parts standards

- Replacing blind rivets

- Safety at work

- Safety information for working on vehicles with automatic engine start-stop function (MSA)

- Safety instructions for handling magnets

- Separating cut determination with a template

- Soldering steel components

- Spot-weld bonding steel components

- Spray gun for cavity sealant

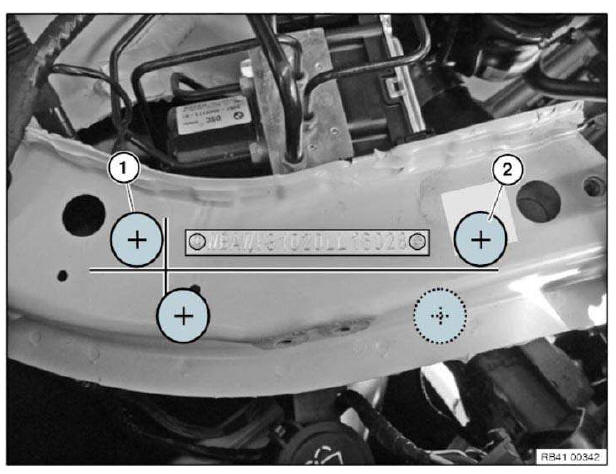

- Stamping vehicle identification number (needle stamping unit)

- Straightening aluminum component on the outer skin

- Straightening aluminum components in structure

- Straightening steel components in the structure

- Straightening steel components on the outer skin

- Touching up paintwork damage

- Use of materials in outer skin

- Vehicle identification number, general

- Welding in reinforcement plate (sheet steel)

- Welding steel components

- Working with 2-component PU cavity foam

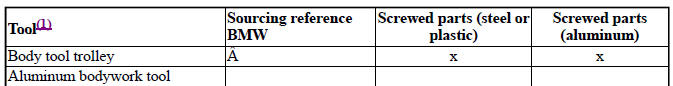

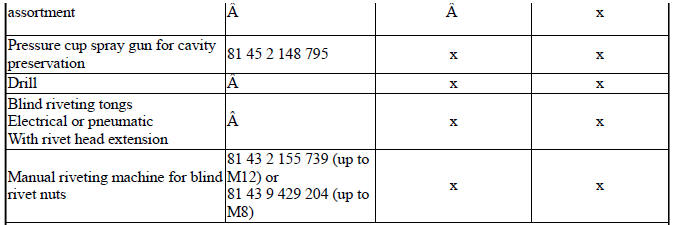

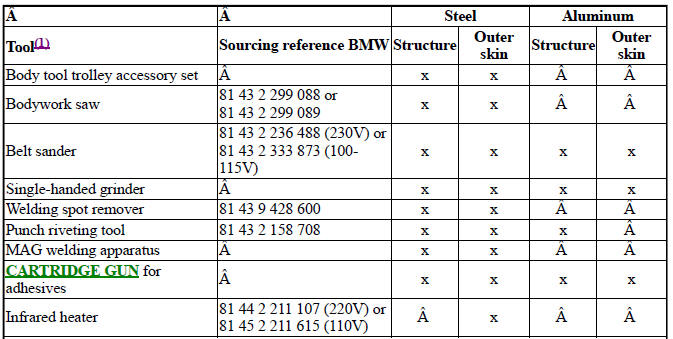

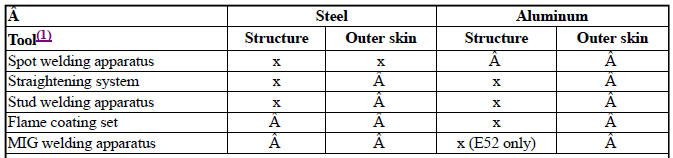

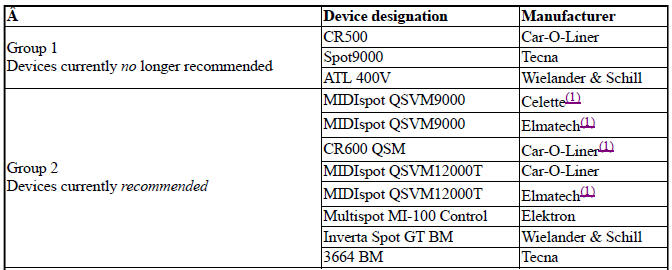

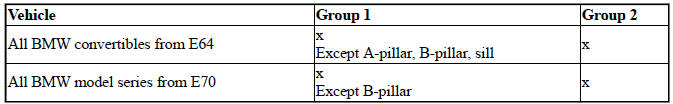

- Workshop equipment (BMW and mini vehicles)

Contents of body, general

Before starting repair work

- BMW i

Checking the body for damage (e.g. following an accident)

General notes

- Quality standard .

- WORKSHOP EQUIPMENT

Safety regulations

- SAFETY AT WORK

- Information on VEHICLE PROTECTION

- INFORMATION ON HAZARDS

Material/new part

- MATERIALS SCIENCE

- EXPENDABLE MATERIALS

- USE OF MATERIALS in outer shell

Handling components

- ELECTRICAL SYSTEM, electronics and fibre optics

- FLOOD DAMAGE

- Passive safety.

- CHASSIS, SUSPENSION AND STEERING

- Retractable hardtop

- Vehicles with hybrid/electric drive

- SEATS/SEAT BELTS

- WHEEL RIM REPAIRS

- HEADLIGHT REPAIRS

Body dimensions

- FRAME DIMENSIONS

- GAP DIMENSIONS

Cavity sealing

- Installation of shaped parts .

- POSITION OF SHAPED PARTS

Vehicle identification number

- GENERAL VEHICLE IDENTIFICATION NUMBER

- ENTER VEHICLE IDENTIFICATION NUMBER

Repair method

- REPAIR STAGE 1A

BMW/MINI/BMW i

- Replacement of screwed-on components

- REPAIR STAGE 1B

BMW/MINI/BMW i

- Repairs to outer skin

- REPAIR STAGE 2

BMW/MINI

- Bonding and riveting

- Welding using a MAG welder

- without straightening bench

BMW i

- Repairs to life module

- Repairs to drive module

- without straightening bench

- REPAIR STAGE 3

BMW/MINI

- Bonding and riveting

- Welding using a spot welding system

- with a straightening bench

BMW i

- Repairs to life module

- Repairs to drive module

- with a straightening bench

Corrosion protection

- GENERAL INFORMATION

Paint

- GENERAL INFORMATION

- INFORMATION/WARNING LABELS

- Separate component and sectional paintwork

NOTES ON THE REPAIR TECHNIQUE USED IN THE MAIN GROUP 41

Two different repair techniques are used in body repair.

These are welding and bonding/riveting.

If the repair instructions do not specify a repair technique, then welding must always be used.

The bonding/riveting repair technique is always described in detail in the repair instructions.

Quality standards must be met.

Blind rivet

1.0 Recommended tools and equipment

- Blind riveting tongs

- Rivet head extension

Setting blind rivets:

- Refer to repair instructions for rivet size.

- Position bore holes for blind rivets in accordance with specification in repair instructions. If necessary, carry over the positions of the blind rivets to the new part.

- Drill holes that exceed the outer diameter of the blind rivet (example Ø 4.2 mm with 4 mm blind rivet and Ø 6.8 mm with 6.5 mm blind rivet).

- The edge of the hole must even on both sides. If necessary, sand down and even out surfaces (e.g. edges of punch rivet connections). Deburr bore holes.

- APPLY ADHESIVE.

- Insert blind rivet. If necessary, remove adhesive that has emerged.

Position blind rivet tool vertically. Use rivet head extension if accessibility is poor.

- Rivet blind rivet with blind rivet tool. In the meantime clean rivet head if dirty with adhesive. Risk of damage to rivet head by penetrating adhesive.

- Seal blind rivet with SEALANT D1 (risk of corrosion).

- Seal cavities after work on vehicle paintwork on with CAVITY PRESERVATION (risk of corrosion).

Bonding on painted/primed surfaces

IMPORTANT: These repair instructions apply only to components of the outer skin and not to structural components.

These include roof outer skin, tail panel, rear side panels and components of the luggage compartment floor.

Follow the vehicle-specific repair instructions.

Only the repair method described there must be used! Conform with safety regulations .

Overview of topics:

- Equipment

- Expiry date of consumables

- Preparation of surface

- Bonding coat

- Hardening times

- Subsequent treatment

- Disposal of adhesive

1.0 Equipment

- CLEANING AGENT R1

- ADHESIVE K5

- CARTRIDGE GUN

2.0 Expiry date of consumables:

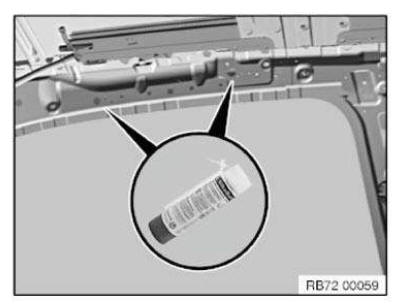

- Glue cartridge is marked with a date.

- Do not use adhesive after this date.

3.0 Preparation of surface:

3.1 Preparation of the surface on the vehicle (series status):

- Establish a level bonding surface (e.g. grinding).

- Do not sand primed bonding surfaces.

If the bonding surface is painted in the vehicle colour, the paint must be completely sanded off.

- If necessary, pre-clean

bonding surfaces with cavity sealing wax remover.

Clean bonding surfaces with cleaning agent R1.

- Allow cleaned surfaces to dry for approx. 5 min.

Bonding surfaces must be completely dry.

3.2 Preparation of the surface on the vehicle (replacement of a bonded component):

- Remove adhesive residue completely from vehicle. Remove all old reinforcement plates if necessary (e. g. rear side panel).

- Do not prime in the area of the bonding surfaces! Adhesive

insufficiently bonds to primer.

If priming is needed after straightening work, cover the bonding surfaces.

- If necessary, pre-clean

bonding surfaces with cavity sealing wax remover.

Clean bonding surfaces with cleaning agent R1.

- Allow cleaned surfaces to dry for approx. 5 min.

Bonding surfaces must be completely dry.

3.3 Preparation of surface on new part:

- Do not remove primer on new part.

Do not grind/sand bonding surfaces.

- Clean bonding surfaces with cleaning agent R1.

- Allow cleaned surfaces to dry for approx. 5 min.

Bonding surfaces must be completely dry.

4.0 Adhesive application:

- Processing temperature of glue cartridge 18 ºC 30 ºC.

- Object temperature, vehicle and new parts, at least 15ºC.

- Do not use an air-powered cartridge gun.

- Insert glue cartridge into cartridge gun, remove cap and allow both adhesive components to emerge. Strip adhesive components uniformly and attach mixing tube.

- Allow approx. 10 cm of mixed adhesive to emerge and then apply the mixed adhesive first on one side of the bonding surface.

- After applying the adhesive, check whether an adhesive component has emerged at the back of the glue cartridge. If yes, break off the bonding procedure. Clean new part. Use new glue cartridge.

- Pot life of mixed adhesive approx. 2 h. A change of mixer is necessary only if no material has flowed through the mixer for a period of 30 min.

- Join components and secure in position.

- Remove excess adhesive.

5.0 Hardening times:

- Do not move the vehicle before the adhesive has hardened.

Check the degree of hardness of the adhesive with a fingernail.

If the adhesive cannot be pressed in any further with a fingernail, the vehicle may be moved (without engine force) for further processing applications (e.g. painting).

- Vehicle strength for driving applications is achieved after:

48 h at an object temperature of at least 15 ºC (corresponds to approx. 18

ºC room

temperature).

Or 1 h in the spray booth (spray booth temperature 80 ºC/object temperature 60 ºC).

- When using radiant heaters, make sure that the object temperature does

not exceed 85 ºC.

Excessively high temperatures will destroy the adhesive.

- Remove contamination caused by adhesive residue immediately.

Hardened adhesive can only be removed mechanically.

6.0 Subsequent treatment:

- Reseal areas which are cavity-sealed as standard.

7.0 Disposal of adhesive:

- Hardened adhesive is disposed of as normal waste.

- Empty glue cartridges are disposed of as normal waste.

- Non-hardened adhesives and mixtures of adhesive and solvent and the like must be disposed of as hazardous waste.

These regulations apply to the Federal Republic of Germany.

For other countries, comply with the (possibly differing) nationally applicable regulations.

Bonding steel on steel

IMPORTANT: These repair instructions apply to structural components.

Such components include engine supports, A-pillars, B-pillars, etc.

Follow the vehicle-specific repair instructions. Only use the repair procedures described there.

Conform with safety regulations .

INFORMATION ON HAZARDS!

Overview of topics:

- Equipment

- Preparing the surface

- Bonding coat

- Hardening times

- Subsequent treatment

1.0 Equipment

- Sandpaper

- CLEANING AGENT R1

- ADHESIVE K1

- CARTRIDGE GUN

2.0 Preparing the surface:

- For better adhesion, remove oxide film and paint from the adhesive areas with a stainless steel wire brush or special sandpaper.

- Clean bonding surfaces with cleaning agent R1.

- Allow cleaned surfaces to dry for approx. 5 minutes.

- Bonding surfaces must be completely dry.

3.0 Adhesive application:

- Processing temperature of glue cartridge 18 ºC - 30 ºC.

- Object temperature, vehicle and new parts, min. 15ºC.

- After applying the adhesive, check whether an adhesive component has emerged at the back of the glue cartridge. If yes, break off the bonding procedure. Clean new part. Use new glue cartridge.

- Join components and secure in position.

- Remove excess adhesive. Do not use solvent cleaning agents.

4.0 Hardening times:

- Refer to NOTES REGARDING ADHESIVE K1

5.0 Subsequent treatment of bonding surfaces:

- Protect the repair area with cavity sealant.

Checklist for front seat

| Event | Check | Action | |

| Has at least one belt tensioner and/or one side airbag been activated? | Yes | Check 1 (when installed):

Check all seat adjustment options of

both front seats. There must be no stiff movement, sticking or other functional problems or noises across the entire adjustment range of all the seat adjustment options. Check head restraints for damage. Check crash-active headrest for activation. Only 2-door model: Check backrest lock. Backrest must unlock and lock easily without any great physical effort. |

If components are OK with

regard to checks 1 and 2, only replace activated belt

tensioner or side airbag. Otherwise, replace faulty parts on the seat/body. Replace belt tensioner, seat belt and, if necessary, side airbag. |

Check 2 (when dismounted):

Check for deformation/damage on the

following components:

Check for visible damage or deformation. |

|||

| No | Check all adjustment options of the head

restraints. Check crash-active headrest for activation. |

Replace faulty parts. | |

| Only seat with integrated seat belt: | |||

| Does the backrest indicator light turn on when the backrest is locked and also when the backrest is shaken? | Yes | Check microswitch of backrest lock and renew if necessary. Check electrical lines and repair if necessary. | If there is still a fault, replace the entire seat |

| No | No further action necessary. | Â | |

Corrosion protection

NOTE: Following repairs, the corrosion protection work already begins with the correct removal of the underbody protection, anti-drumming layer and seam sealing in the repair area.

The PRODUCTS RECOMMENDED by BMW are optimized with regard to corrosion protection.

1.0 Removing and applying sealant:

1.1 Removing sealant:

IMPORTANT:

- Do not burn off PVC material (sealant) with an autogenous torch or similar or heat to temperatures above 180 ºC. This would generate highly corrosive hydrochloric acid and release harmful vapor.

- The new sealant does not adhere appropriately to burnt polyvinyl chloride material and hence subsequent rust creep is possible.

Remove PVC material with a rotating steel brush, or heat PVC to maximum 180 ºC with a hot air blower and scrape off with a spatula.

Remove PVC material with a rotating steel brush, or heat PVC to maximum 180 ºC with a hot air blower and scrape off with a spatula.

1.2 Applying sealant:

Prime and seal all weld seams that are sealed with sealant in original condition immediately after repair work. Replace damaged or removed anti-drumming layers.

NOTE: Required spray gun for sealant (order number 81 49 0 300 887).

Seal blind rivet with SEALANT (risk of corrosion).

2.0 Basics of cavity preservation:

Apply cavity preservation after all body repairs.

Concluding cavity preservation is the most important part of all corrosion protection measures.

Use the cavity protection spray only for smaller-scale straightening work where the parts in question are easily accessible. Use the PRESSURE CUP GUN for all other repairs. Cavity protection agent is available in different container sizes.

Use the relevant sensors with tubes for the different cavity areas.

IMPORTANT: Incorrectly performed cavity protection can, especially in the case of steel/aluminum joints, give rise to a non-calculable product liability and safety risk.

The best repair is worth nothing if the subsequent cavity protection measures are not conscientiously carried out.

2.1 Cavity preservation of steel parts:

New doors and lids must be sealed with cavity protection agent after being painted.

New sheet-metal parts or cavities, weld seams and folds formed by new sheet-metal parts must be sealed with cavity protection agent after being painted.

The cavities affected must be sealed with cavity protection agent after all straightening work.

2.2 Cavity preservation of aluminum parts:

New doors, lids and side panels made of aluminum are not sealed with cavity protection agent.

After all straightening work on aluminum components, the cavities affected must be sealed with cavity protection agent after being painted.

After all welding work (E52 only) on aluminum components, the cavities affected must be sealed with cavity protection agent after being painted.

Cavities, seams and folds formed from new sheet metal parts or extruded profile must be sealed with cavity protection agent after being painted.

Emc screws

(EMC = Electro-Magnetic Compatibility)

1. Purpose:

- EMC SCREWS are used in the Bonding/Riveting repair method to re-establish bonding transition.

- They assume the function of welded joints, which ensure transition to ground between the individual components.

- The punch or blind rivets used in the repair do not guarantee permanent bonding transition between the individual components!

- The EMC screws ensure the operational reliability and safety of the electrical/electronic components following repairs!

2. Procedure, aluminum front end:

- Each welded joint which is opened must be replaced by at least 2 EMC screws.

- Position the 2 screws on the flange on which the weld seam has been separated. In the event of partial replacement, position the screws in the area of the component overlap.

- In the case of repairs using partial replacement, the number of EMC screws described in the repair instructions must be fitted.

- Drill holes to a diameter of 4.2 mm and insert screws.

- Seal EMC screws with PU sealing material (risk of corrosion).

3. Procedure, steel body:

- Install the number of EMC screws described in the repair instructions.

- Drill holes to a diameter of 4.2 mm and insert screws.

- Seal EMC screws with PU sealing material (risk of corrosion).

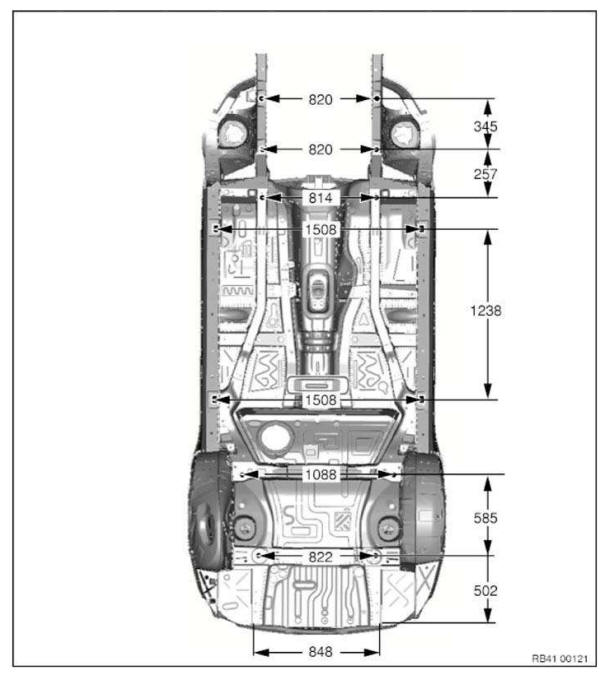

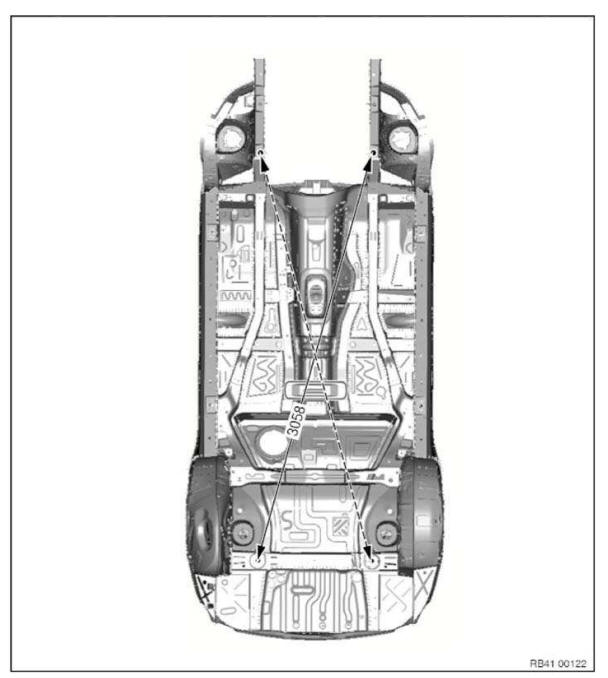

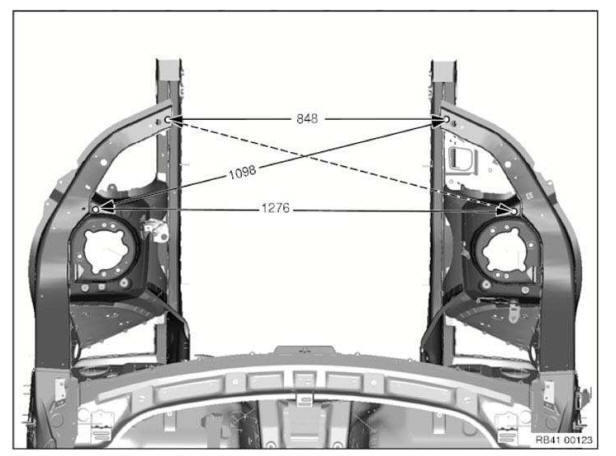

Frame alignment control dimensions, body

Dimensions in mm.

Measurement tolerances:

- ≤ 1000 mm Â+- 1.5 mm

- ≥ 1000 mm Â+- 2.5 mm

The control points shown serve to check the body and the set of attachments.

The specified dimensions/measurements refer to the center point of the bore/screw.

Underbody view 1

Underbody view 2

Top view, front end

The specified dimensions refer to removed assemblies.

View, B-pillar

Measurement a=1556 mm between screw-on points of door brakes.

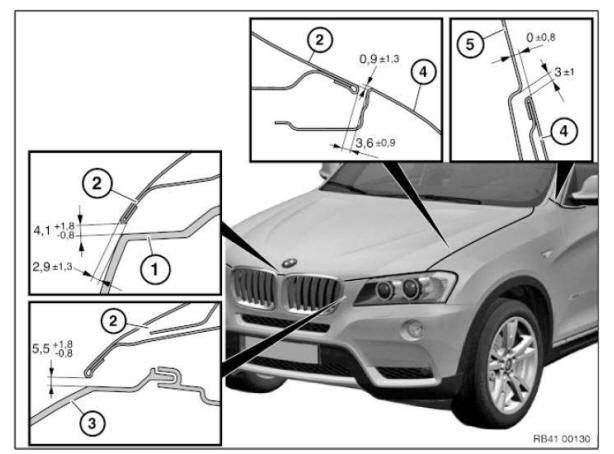

Gap dimensions, body

The dimensions specified in this information are applicable at an object temperature of 20 ºC. The aim of adjustment is to achieve a uniform gap.

Symmetry of the gaps between left and right sides of the vehicle has top priority.

The door gaps must not deviate between the front and rear door gap by more than 1.0 mm.

No gap dimension are specified for components which cannot be adjusted.

Dimensions in mm

- Panel, bumper, front

- Headlight

- Rear door

- Rear side walls

General instructions on paintwork

The marked area serves as reference value for paintwork. This area may differ from the illustration for technical painting reasons.

Touching-up areas are taken into account.

Special procedure for matte paintwork: Matte paintwork cannot be touched up since the painted surface cannot be polished.

General notes for labelling with adhesive films

In the event of a repair the adhesive films must be partially or completely replaced. The basic procedure for all areas of the vehicle is described below.

In addition, vehicle-specific repair instructions are available.

1. Preparation: Wash and dry vehicle. Rework with compressed air as required in area of joints.

Clean complete component surface with glass cleaner (BMW part number 83 12 0 396 775). Also clean the inside of the component in areas, in which adhesive films are applied.

Only carry out repair work with clean hands!

IMPORTANT: Labels can only be applied to recently painted components after a waiting period of 2 weeks . The paint hardening is only fully completed after this time.

2. Procedure for applying labels: All adhesive films in the repair kit are marked with numbers. Prepare the required plastic films prior to start of repairs.

The templates included in the repair kit assist orientation. A straight line running over the different components is the top priority.

Pull off the templates positioning of the adhesive films.

Only throw away templates after completion of all repair work, as some templates are used several times.

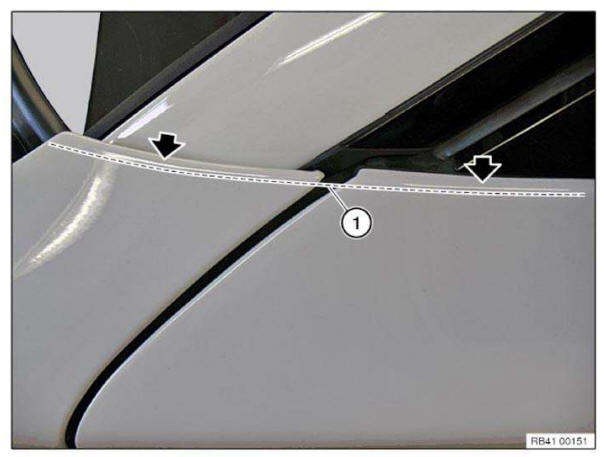

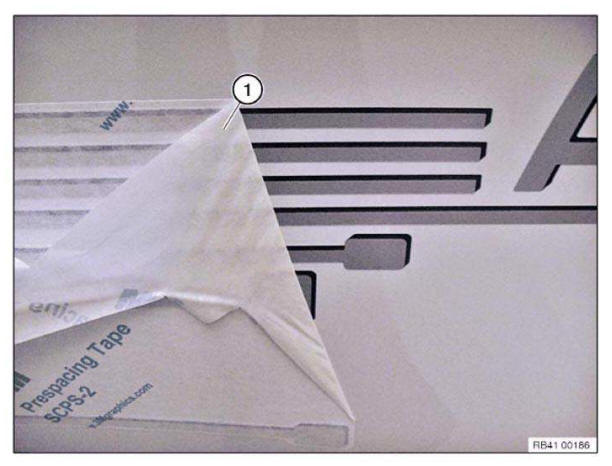

Templates are always applied along the light edge (1). The light edge is the reflection of the light source in radius (see arrow).

Roughly align the adhesive film using a template.

For large adhesive films, pull off the first 20 cm of protective film and fold back the edge.

Align and lightly press down the adhesive film. Use only one finger for this and not the entire hand so that air pockets are unable to form under the adhesive film.

Pull off the remaining protective film and press down the adhesive film from front to rear and from inside to outside.

If faults are made in applying the adhesive film, it can be pulled off and repositioned several times. When no further corrections have to be made, use a squeegee to press down the adhesive film firmly from inside to outside.

Lay protruding ends of the adhesive film around the component edge and press down firmly.

Carefully pull off backing film (1) at an acute angle.

Grinding aluminum components

1.0 Recommended tools and equipment

Grinding work on the outer skin:

-

To carry out grinding work by hand or machine, you must use the recommended tools and

equipment.

The workbay can be cleaned with conventional extractor systems (low dust concentration).

Grinding work on the structure (except Z8):

-

To carry out grinding work by hand or machine, you must use the recommended tools and

equipment.

The workbay can be cleaned with conventional extractor systems (low dust concentration).

Z 8 Spaceframe structure:

-

To carry out machine grinding on the structure, you must use the recommended device with

grinding dust extractor facility.

The workbay must be cleaned with the recommended explosion-proof extractor system.

High dust concentration, explosion hazard!

2.0 Grinding outer skin and structure

Do not use any abrasives (grinding wheels, paper, etc.) which contain iron (risk of corrosion).

Always replace abrasives which have already been used to treat steel (risk of corrosion).

Use stainless steel wire brushes only (risk of corrosion).

Reduce speed of grinding machines. Excessive speeds cause a smearing effect.

Do not use coarse abrasive grains (only ≥ 80).

Do not grind notches into the material (risk of cracking).

Do not grind the material thin.

Grinding steel parts

1.0 Recommended tools and equipment

- Tools are recommended for manual grinding work.

- Machines/equipment are recommended for machine grinding work.

2.0 Grinding outer shell and structure

Always replace abrasives which have already been used to treat aluminum (risk of corrosion).

Do not grind the material thin.

Handling airbags and restraint systems

1.0 Airbags and restraint systems

- In the case of vehicles with airbags and restraint systems observe the relevant SAFETY INSTRUCTIONS .

-

When straightening work is carried out on the body there is a risk of airbags being accidentally

activated when the battery is connected.

Because of this risk the battery ground cable must be DISCONNECTED prior to all repair work on the body.

HANDLING COMPONENTS AFTER FLOOD DAMAGE

Flood damage can occur if the permissible fording depth of a vehicle is exceeded. Ingress of water can cause damage to the engine (water shock) or components.

Because dirt particles generally enter into the component with the water (e.g. starter motor, wiring harness), the components need to be thoroughly inspected.

Residual moisture in the components leads to corrosion (increased contact resistance in the component), which can lead to a component failure at a later time.

If water ingress into the electrical components cannot be ruled out, it is recommended to replace the component to ensure correct functioning through the vehicle lifetime.

Handling electrical system and electronics

1.0 Battery

- Explosion hazard in the vicinity of the battery during welding and grinding work. The battery must be REMOVED .

2.0 Control units

- Control units with visible mechanical damages and/or electrical damages caused by accidents must be replaced.

- The following risks exist when the battery is connected:

- Damage to control units resulting from welding work on the body or a line short circuit.

- Accidental activation of airbags during straightening work on the body.

Because of these risks the ground cable must be DISCONNECTED prior to all repair work.

- Control units are designed for a temperature of 65 ºC. The temperatures in a spray booth do not pose any problems. If a vehicle is in the spray booth at a displayed temperature of 80ºC, the actual temperature of the vehicle is ≤ 60 ºC (object temperature).

- Protect control units against the influence of heat >65 ºC (e.g. during welding and drying work with infrared beams or hot air blowers).

3.0 Electrical wires and wiring harnesses

- Protect electrical wires and wiring harnesses against damage (e.g. during straightening and grinding work).

- Protect electrical wiring and wiring harnesses against the influence of heat >65 º C (e.g. during welding and drying work with infrared beams or hot air blowers).

- Do not kink electrical wiring.

4.0 Optical fibres

- Follow instructions for handling OPTICAL FIBRES .

Information on hazards

1. Aluminum

| Hazards/effects | Measures/regulations |

| Repair stage 1 and 2: No hazards/effects | none |

Repair stage 3: (Welding - only E52)

|

|

|

|

2. Carbon

| Hazards/effects | Measures/regulations |

| Repair stage 1: No hazards/effects | none |

Repair stage 2 and 3:

|

|

|

|

Information on metal filler

IMPORTANT: Note the following information before starting to apply metal filler!

- Country-specific safety and industrial safety regulations

- Material safety data sheet of manufacturer

- Processing instructions on the packaging

Storage: Dry at 15ºC to 25 ºC.

Shelf life: The packaging is marked with a date.

Do not use the metal filler after this date.

Surface pre-treatment: Grind surface to a metallic bright-finish. The surface must be clean, dry and free from grease.

Clean the surface with a cleaning agent R1 and let it vent for 2-3 minutes.

Processing: The working temperature of the metal filler must be at least 18ºC.

- Metal filler

- Hardener

NOTE: The mixture ratio refers to the volume.

Mix metal filler in mixture ratio of 5:2. Mix components thoroughly and free of pores.

IMPORTANT: Do not stir components. Danger of air pockets in metal filler!

Working life of the metal filler is approx. 45 minutes.

Applying filler: Apply pressure to apply a thin layer of metal filler. Carefully coat all edges in gaps with filler.

Then fill gap completely with filler. Apply filler with about 30% excess because the filler will significantly shrink during hardening. A second application of metal filler is not possible due to poor adhesion.

IMPORTANT: Use a narrow spatula to fill the gaps. Apply the filler in one draw if possible. Danger of formation of pores in gaps!

No restrictions related to the layer thickness.

Hardening time: The metal filler must be hardened using a short-wave infrared heater.

- 10 minutes at 50 ºC - pre-hardening (avoid formation of bubbles/blisters and pores)

- 10 minutes at 75 ºC - 1st stage hardening

- 10 minutes at 85 ºC - 2nd stage hardening (avoid material shrinkage)

IMPORTANT: In the first 10 minutes, the temperature of 50ºC may not be exceeded. In contrast, a temperature that is too low may be equalized by extending the time.

NOTE: When the heater is used for the first time, the distances that match the temperature must be determined. Switch the heater on and change the distance until the surface temperature of the metal filler no longer changes for a period of 2 minutes. Measure the temperature with a temperature gauge. When optical temperature gauges are used (Epsilon value 0.92-0.95), the heater must be switched off briefly during the measurement. Record the measurement

Post-processing

WARNING: When grinding, wear a fine dust mask with particulate filter P2-P3!

After cooling, the metal filler can be machined.

Pores and faulty spots that become visible after grinding the surface must be closed with polyester filler (BMW Colour system).

Special procedure for pores: Use a Ø4.2mm drill. Turn the drill by hand to expand the pores in v shape. by t Fill cavities with polyester filler.

Paintwork: Perform paintwork according to the specifications in the painting handbook.

IMPORTANT: When using temperature-controlled infrared radiators, damage to adhesive bonds, paint and vehicle components can occur when drying spatula and filler.

The temperature sensors in the infrared radiator only operate reliably on large, even surfaces.

On small surfaces such as C-pillars or sills, often only a colder, adjacent area is measured.

This leads to actual surface temperatures of up to 130ºC, even if only 70ºC is set on the infrared radiator.

When the rear side walls are partially replaced by bonding and riveting, these high temperatures can lead to a visible pattern in the area of the joint.

Remedy: Check the surface temperatures on small component surfaces during the drying process with an external temperature sensor.

The general rule is: The surface temperatures must not exceed 85ºC.

Metal filler disposal: Hardened metal filler is disposed of as normal waste.

Empty packaging is disposed of as normal waste.

Non-hardened metal filler and mixtures of metal filler with solvent and the like must be disposed of as hazardous waste.

These regulations apply to the Federal Republic of Germany.

For other countries, comply with the (possibly differing) nationally applicable regulations.

Information on using cleaning agent/paints (personal protection equipment)

WARNING: Use of cleaning agents/paints not compliant with instructions can cause serious injuries or burns! Handling cleaning agents/paints can trigger allergic skin and respiratory reactions!

IMPORTANT: Observe following instructions:

- Store cleaning agents/paints only in a secure cabinet.

- Keep cleaning agents/paints away from naked flames and other sources of ignition.

- Protect cleaning agents/paints from high temperatures and direct sunlight.

- Always keep an eye douche on hand, change the water regularly (once a month).

IMPORTANT: Observe following instructions before use:

- Manufacturer's instructions (on container/packaging)

- Hazard warnings (on container/packaging)

- Manufacturer's instructions on package insert

- Material safety data sheet of manufacturer

- National market regulations

IMPORTANT: Observe following instructions during use:

- Do not eat, drink or smoke while working with these products.

- Avoid direct contact with skin and eyes.

- Wear personal protective clothing/equipment.

- Ensure that all enclosed areas are well ventilated or extract fumes directly.

- Immediately change working clothes soiled with cleaning agent/paint.

- After finishing work, wash your hands and apply protective skin cream.

IMPORTANT: Follow hazard warnings and wear personal protection equipment!

First Aid:

-

If product comes in contact with eyes, immediately flush with running water for about 10 - 15 minutes.

Seek the advice of eye specialist.

- In the event of skin contact and where applicable an allergic skin reaction, clean the affected areas immediately with soap and water and then apply silicone-free skin cream. Seek advice of physician.

- If an adhesive product is swallowed, rinse mouth/parts of mouth thoroughly with running water. Drink 1- 2 glasses of water. Do not induce vomiting. Consult a doctor.

- After inhaling vapors ensure ample supply of fresh air. Keep calm, keep respiratory tracks clear and call doctor.

Recycling: Dispose of cleaning agents/paints in a professional manner! Observe national/country-specific disposal regulations.

Information on vehicle protection

- Vehicle parts located in the repair zone or threatened by heat, sparks or dust, must be removed or covered.

IMPORTANT: Do not use flammable or dirty material for covering.

INFORMATION/WARNING LABELS

Missing or damaged labels (e. g. tire pressure) must be replaced.

→ Overview of the INSTALLATION LOCATION

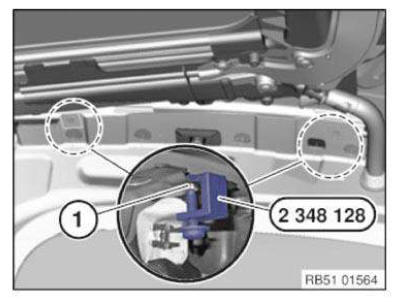

Installation solution for straight shank/hexagon rivet nut

Protection measures!

- Wear safety goggles

- Wear protective gloves

Hexagon/straight shank rivet nut (up to thread 8) with hand rivet gun ZS308

IMPORTANT: Risk of damage! Failure to comply with these instructions may result in the drill bit slipping and causing significant paintwork damage.

1. Mark position of bore and then punch-mark component

IMPORTANT: If the determined drill bit diameter is not observed:

- the knurling on the straight shank rivet nut is rendered useless

- the component will be damaged when the straight shank rivet nut is inserted

Determining suitable drill bit:

Depending on the rivet nut shank diameter, the next drill bit diameter higher (5/10 step) can be used.

E.g. with a shank diameter of 10.1 mm, the 10.5 mm drill bit can be used. The 11.0 mm drill bit must not be used.

2. Drill bore with determined drill bit and deburr, pilot-drill with a smaller drill bit if necessary

3. Clean component, eliminate paintwork damage if necessary

IMPORTANT: To avoid corrosion, stop chips/swarf by means of cavity sealing.

Follow INSTRUCTIONS ON CORROSION PROTECTION.

4. Preserving cavity

IMPORTANT: Follow manufacturer's operating instructions.

Make sure straight shank rivet nut correctly contacts component.

5. Set rivet nut with hand rivet gun

NOTE: According to the manufacturer, the pictured tool is suitable up to an M8 thread.

Hexagon/straight shank rivet nut (up to thread M12) with hand rivet gun MB512

IMPORTANT: Follow manufacturer's operating instructions.

Make sure hexagon rivet nut correctly contacts component.

Set rivet nut with hand rivet gun

NOTE: According to the manufacturer, the pictured tool is suitable up to an M12 thread.

Installing a cavity sealing with 2-component pu cavity foam

SOURCING REFERENCE for cavity foam HS1.

IMPORTANT: The cavity foam may only be use for cavity sealing at the points at which cavity sealing is present as standard!

The following repair represents the replacement of a shaped part for the cavity sealing by the use of cavity foam.

This type of cavity sealing is used at points at which shaped parts cannot be used for repairs.

This is the case when large amounts of heat occur (e.g. due to welding, soldering or tin-plating) in the direct vicinity or at the point of the standard cavity sealing.

It is not possible here to install shaped parts for the cavity sealing because of the fire risk! To replace shaped parts with cavity foam at further locations, adopt the procedure shown here and adapt it to the relevant ratios.

It must be ensured that the cavity sealing is fully completed.

NOTE: Check the accessibility for the spraying pipe of the cavity foam to the affected cavity after removing the defective parts.

Properties of cavity foam HS1:

- 2-component PU foam, solvent-free.

- Excellent flow capacity, enabling complete sealing of cavities.

- Good strength, preventing slipping in cavities.

- Low water absorption, preventing corrosion.

- Ideal for use as insulating and sealing compound.

Information on dangers/hazards:

- Avoid eye and skin contact.

Wear eye protection, solvent-resistant protective gloves and protective clothing.

- Do not inhale.

Apply in well ventilated rooms only.

WARNING: Application time after mixing process: within 8 minutes!

- Completely empty open can after use.

- Residual amounts which are not used can cause the can to explode on account of a chemical reaction (buildup of heat)!

- Alternatively, cool the can containing the non-removed residual amount for several hours in cold water.

- Do not eat, drink or smoke while working with these products.

- Keep heat and ignition sources far away.

- Read the manufacturer's information on hazards/dangers (printed on the can) prior to application.

Processing instructions:

- Observe the expiry date on the cartridge.

Do not use spray can after the expiry date has passed. After the Use by date the properties of the cavity foam will no longer meet the requirements of the BMW Group.

- Cavity preservation of the repair area possible after an air drying time of 1 hour.

- Surface must be clean, free of dust, grease, oil and separating agents .

- Application temperature at least 15 ºC. Optimally 20 ºC.

IMPORTANT: Foam expands many times over as it sets (change in volume).

-

Before applying to the vehicle, fill a clearly visible cavity of corresponding size with foam on a used part.

This enables an optimal dosage (i.e. spraying time) to be specified for filling the cavity on the vehicle with foam.

- Tape off open passages to visible areas with adhesive tape to prevent foam from escaping.

- The setting takes approx. 30 minutes. Mechanical processing (e.g. drilling, cutting, etc.) is then possible

- Cavity preservation of the repair area possible after an air drying time of 1 hour.

- Remove fresh, non-hardened polyurethane foam with adhesive remover 208.

Sourcing reference: BMW Parts Department.

Hardened polyurethane foam can only be removed mechanically.

- Excess hardened polyurethane foam can be disposed of as residual waste.

Cans that are not entirely empty or are unused and have an expired expiry date are classed as hazardous waste.

Observe country-specific waste disposal regulations.

- Observe the manufacturer's processing instructions (printed on the can).

Installing cavity sealing (expanded)

NOTE: Carry over schematic diagram to the relevant vehicle type.

The following repair represents the procedure for an already expanded cavity acoustic baffle.

The cavity acoustic baffle remains on the body in this instance.

Before these work steps, prepare the new part so that it is ready to install (adapting, cutting to size, applying welding primer etc.).

Clean contact surface (1) with cleaning agent R2.

Apply a bead (2) approx. 15 mm high of SEALANT D2 to contact surface (1).

If necessary apply sealant D2 somewhat thinner on each side, to prevent the sealant from running.

Fit, secure and weld up new part.

WARNING: Ensure adequate ventilation over entire processing period.

Installing cavity sealing (not expanded)

NOTE: Carry over schematic diagram to the relevant vehicle type.

The following repair represents replacement of a cavity acoustic baffle.

Before these work steps, prepare the new part so that it is ready to install (adapting, cutting to size, applying welding primer etc.).

Sand contact surface of cavity acoustic baffle (1) with coarse-grained sandpaper (grain 50-100).

Clean contact surface (1) with cleaning agent R2.

Apply a bead approx. 15 mm high of SEALANT D2 to contact surface (1).

If necessary apply sealant D2 somewhat thinner on each side, to prevent the sealant from running.

Attach cavity acoustic baffle in specified position (see old part).

Fit, secure and weld up new part.

WARNING: Ensure adequate ventilation over entire processing period.

Materials science

1. Aluminum

1.1 Chassis/suspension components READ and observe the Notes on chassis/suspension components before handling aluminum.

1.2 Material influences

| Causes | Effects/remedies |

| A galvanic element is created under the

effects of moisture by contact with

materials such as copper, tin, nickel, iron

and zinc. Tools also used for work on steel components can implant steel particles in the softer surface of an aluminum component. Surfaces are attacked when fluxing agents are used. Aluminum/steel grinding dust from adjoining working areas. |

This plating process causes aluminum to be removed

from the connection point. This results in surface corrosion or pitting. New parts and accessory parts which have been approved by the BMW Group for aluminum (screws, washers, nuts etc.) have undergone special surface treatment. Such parts must not be replaced by conventional parts. NOTE: Damaged parts lose this protection and must be specially coated or replaced. Damage caused by contact corrosion is excluded from the warranty. Surface corrosion or pitting occurs. A separate tool set is available for processing/machining aluminum. Soldering is not permitted for joining aluminum components. Risk of corrosion from chemical factors. This results in surface corrosion. Erection of protective barriers. |

1.3 Machining properties

| Properties of aluminum compared with steel | Effects |

| Aluminum parts are

magnetically neutral. Elasticity is only 1/3 as high. Elongation failure is approx. 50 % slighter. Electrical conductivity is almost 4 times higher. Material expansion during heating is twice as high. Thermal conductivity is 3 times higher. Structural transformation between 200 ºC and 250 ºC Aluminum shows no annealing colors. |

Attachment with magnetic tools/working aids is not possible. Convertibility is limited in comparison with steel. Overstretching the material results in strain-hardening and an increased tendency of cracking. Electric welding methods require different equipment (MIG welding). The material expands more markedly. Shorter heat treatment is necessary for removing dents. Heat is drained more quickly. Adjoining working areas are affected more heavily e.g. during welding. Elongation characteristics and thus plasticity are improved. Strength is reduced. IMPORTANT: No heat treatment during repair work on the vehicle structure! Workshop operation doesn't make it possible to control the temperature to sufficiently exact levels. The melting point is 650 ºC. Once the melting temperature has been reached, the material begins to flow without any further indications. The temperature can only be estimated by means of the paint coloring and the surface warpage. IMPORTANT: Do not use thermo crayons. Not suitable for workshop operation because the paint runs too quickly. |

1.4 Storage

| Characteristic features of aluminum | Special measures |

| Corrosion (ageing) in damp

environments. Contact corrosion in event of contact e.g. with steel components. Susceptibility to paint infiltration. |

Store aluminum components in a dry place. Always store aluminum components separately or in isolation from steel components. Do not damage factory protective layer of the surface since this would cause oxidation. Failure to comply with this requirement would result in more painting work. |

Notes for repairing aluminum rims

In general, the economic viability must be checked prior to the repair.

It is possible to repair the following damage (applies to cast aluminum rims labelled as AlSi7 AlSi11, AlSi12):

- Depth of the damage in the aluminum at maximum 1 mm

- Distance of the damage from the outer rim edge at maximum 50 mm

- Paintwork damage on the remaining wheel rim

It is not possible to repair the following damage:

- Deformation and cracks

- Polished, forged aluminum wheel rims are unsuitable for repair.

Notes on adhesive K1

IMPORTANT: Note the following information before starting to apply adhesive!

- Country-specific safety and industrial safety regulations

- Material safety data sheet of manufacturer

- Processing instructions on glue cartridge

Storage: Dry at 15º- 25 ºC.

Shelf life: The glue cartridge is marked with a date.

Do not use the adhesive after this date.

Surface pre-treatment: The PRE-TREATMENT depends on the material to be bonded and its coating.

Required cartridge gun: OVERVIEW OF GLUE CARTRIDGE GUNS

Do not use compressed-air-operated cartridge guns!

Preparing the glue cartridge: Opened glue cartridges may be used again before the expiry date as long as a new mixing tube is used.

The working temperature of glue cartridge must be at least 20ºC.

Insert glue cartridge into cartridge gun, remove cap and allow both adhesive components to emerge. Strip adhesive components uniformly and attach mixing tube. Only use mixing tubes supplied with glue cartridge.

Allow approx. 10 cm of mixed adhesive to emerge.

Only after this apply the mixed adhesive to one side of the bonding surface.

Application time of mixed adhesive approx. 2 hours. A change of mixer is only necessary if over a period of 1 hour no material has flowed through the mixer.

2-component adhesive application: Read the vehicle-specific repair instructions to determine the thickness and positioning of the adhesive bead.

After applying the adhesive, check whether an adhesive component has emerged at the back of the glue cartridge. If yes, break off the bonding procedure. Clean new part. Use new glue cartridge.

Remove contamination caused by adhesive residue immediately.

Hardened adhesive can only be removed mechanically.

Hardening time:

Do not move the vehicle before the adhesive has hardened.

Check the degree of hardness of the adhesive with a fingernail.

If the adhesive cannot be pressed in any further with a fingernail, the vehicle may be moved (without engine force) for further processing applications (e.g. painting).

Vehicle strength for driving applications is achieved after:

48 hours at an object temperature of 15ºC.

10 hours at an object temperature of 23ºC.

1 hour at an object temperature of 60ºC.

0.5 hours at an object temperature of 85ºC.

IMPORTANT: When using radiant heaters, make sure that the object temperature does not exceed 85 ºC.

Excessively high temperatures will destroy the adhesive.

Disposal of adhesive: Hardened adhesive is disposed of as normal waste.

Empty glue cartridges are disposed of as normal waste.

Non-hardened adhesives and a mixture of adhesive and solvent and the like must be disposed of as hazardous waste.

These regulations apply to the Federal Republic of Germany.

For other countries, comply with the (possibly differing) nationally applicable regulations.

Notes on adhesive K2

IMPORTANT: Note the following information before starting to apply adhesive!

- Country-specific safety and industrial safety regulations

- Material safety data sheet of manufacturer

- Processing instructions on glue cartridge

Storage: Dry, at 15 ºC - 25 ºC.

Shelf life: The glue cartridge is marked with a date.

Do not use the adhesive after this date.

Surface pre-treatment: Refer to vehicle-specific repair instructions or Notes.

Required cartridge gun: CARTRIDGE GUN 81 43 2 159 881/883 for 195 ml container

IMPORTANT: Set speed control (1) to interval stage 3 to prevent overloading the cartridge gun.

CARTRIDGE GUN 81 49 2 355 475 for 2x290 ml container

Preparation of the glue cartridge (195 ml): Opened glue cartridges may be used again before the expiry date as long as a new mixing tube is used.

The working temperature of glue cartridge must be at least 20ºC.

Application time of the adhesive approx. 20 min

IMPORTANT: At working temperatures above 30ºC, the application time of the adhesive is reduced to 10 min!

Insert glue cartridge into cartridge gun, remove cap and allow both adhesive components to emerge. Strip adhesive components uniformly and attach mixing tube. Only use mixing tubes supplied with glue cartridge.

Allow approx. 10 cm of mixed adhesive to emerge.

Only after this apply the mixed adhesive to one side of the bonding surface.

Preparation of the glue cartridge (2x290 ml): Opened glue cartridges may be used again before the expiry date as long as a new mixing tube is used.

The working temperature of glue cartridge must be at least 20ºC.

Application time of adhesive at 28 ºC 35 min and at 18 ºC 50 min Remove the sealing cap on the back of the glue cartridge. Remove the safety and connecting pipe. Puncture the glue cartridges open. Attach the connecting pipe and insert the glue cartridge in the cartridge gun. Allow both adhesive components to emerge. Strip adhesive components uniformly and attach mixing tube. Only use mixing tubes supplied with glue cartridge. Allow approx. 10 cm of mixed adhesive to emerge.

Only after this apply the mixed adhesive to one side of the bonding surface.

2-component adhesive application: Read the vehicle-specific repair instructions to determine the thickness and positioning of the adhesive bead.

After applying the adhesive, check whether an adhesive component has emerged at the back of the glue cartridge. If yes, break off the bonding procedure. Clean new part. Use new glue cartridge.

Remove contamination caused by adhesive residue immediately.

Hardened adhesive can only be removed mechanically.

Hardening time: Do not move the vehicle before the adhesive has hardened. The following hardening times apply unless the specifications in the vehicle-specific repair instructions indicate otherwise:

Adhesive K2 (2x290 ml):

IMPORTANT: During the initial 12 hours, no accelerated hardening with a heat gun or heat chamber is permitted!

The solidity for installation work on the vehicle is reached after: 12 hours at an object temperature of 18ºC.

Vehicle strength for driving applications is achieved after: 48 hours at an object temperature of 18ºC.

IMPORTANT: When a complete side frame is replaced (without partial replacement), the hardening period will increase to 24 hours until the beginning of installation work.

Disposal of adhesive: Hardened adhesive is disposed of as normal waste.

Empty glue cartridges are disposed of as normal waste.

Non-hardened adhesives and mixtures of adhesive and solvent and the like must be disposed of as hazardous waste.

These regulations apply to the Federal Republic of Germany.

For other countries, comply with the (possibly differing) nationally applicable regulations.

Notes on adhesive K3

IMPORTANT: Note the following information before starting to apply adhesive!

- Country-specific safety and industrial safety regulations

- Material safety data sheet of manufacturer

- Processing instructions on glue cartridge

Storage: Dry at 15º- 25 ºC.

Shelf life: The glue cartridge is marked with a date.

Do not use the adhesive after this date.

Surface pre-treatment: See vehicle-specific repair instructions

Required cartridge gun: OVERVIEW OF GLUE CARTRIDGE GUNS

Preparing the glue cartridge: Do not prepare the glue cartridge until just before applying the adhesive.

The working temperature of glue cartridge must be at least 18ºC.

Pot life of adhesive is approx. 10 minutes at 25 ºC.

Insert glue cartridge into cartridge gun, remove cap and allow both adhesive components to emerge. Strip adhesive components uniformly and attach mixing tube. Only use mixing tubes supplied with glue cartridge.

Before starting to apply adhesive, allow approx. 1 mixing tube length of mixed adhesive to emerge. Only then apply the mixed adhesive to one side of the bonding surface.

Opened cartridges may be used again before the expiry date as long as a new mixing tube is used.

2-component adhesive application: Read the vehicle-specific repair instructions to determine the thickness and positioning of the adhesive bead.

Hardening time: See vehicle-specific repair instructions

Adhesive disposal: Hardened adhesive is disposed of as normal waste.

Empty glue cartridges are disposed of as normal waste.

Non-hardened adhesives and mixtures of adhesive and solvent and the like must be disposed of as hazardous waste.

These regulations apply to the Federal Republic of Germany.

For other countries, comply with the (possibly differing) nationally applicable regulations.

Notes on adhesive K4

IMPORTANT: Note the following information before starting to apply adhesive!

- Country-specific safety and industrial safety regulations

- Material safety data sheet of manufacturer

- Processing instructions on glue cartridge

Storage: Dry at 15º- 25 ºC.

Shelf life: The glue cartridge is marked with a date.

Do not use the adhesive after this date.

Surface pre-treatment: See vehicle-specific repair instructions

Required cartridge gun: OVERVIEW OF GLUE CARTRIDGE GUNS

Preparing the glue cartridge: Do not prepare the glue cartridge until just before applying the adhesive.

Opened glue cartridges may be used again before the expiry date as long as a new mixing tube is used.

The working temperature of glue cartridge must be at least 18ºC.

Working life of adhesive is approx. 10 minutes.

Insert glue cartridge into cartridge gun, remove cap and allow both adhesive components to emerge. Strip adhesive components uniformly and attach mixing tube. Only use mixing tubes supplied with glue cartridge.

Before starting to apply adhesive, allow approx. one half mixing tube length of mixed adhesive to emerge. Only then apply the mixed adhesive to one side of the bonding surface.

2-component adhesive application: Read the vehicle-specific repair instructions to determine the thickness and positioning of the adhesive bead.

Hardening time: The bonded connection will be resistant after 30 minutes.

Disposal of adhesive: Hardened adhesive is disposed of as normal waste.

Empty glue cartridges are disposed of as normal waste.

Non-hardened adhesives and mixtures of adhesive and solvent and the like must be disposed of as hazardous waste.

These regulations apply to the Federal Republic of Germany.

For other countries, comply with the (possibly differing) nationally applicable regulations.

Notes on adhesive K5

IMPORTANT:

Note the following information before starting to apply adhesive!

- Country-specific safety and industrial safety regulations

- Material safety data sheet of manufacturer

- Processing instructions on glue cartridge

Storage: Dry at 15º- 32 ºC.

Shelf life: The glue cartridge is marked with a date.

Do not use the adhesive after this date.

Surface pre-treatment: See vehicle-specific repair instructions

Required cartridge gun: OVERVIEW OF GLUE CARTRIDGE GUNS

Preparing the glue cartridge: The working temperature of glue cartridge must be at least 20ºC.

Opened glue cartridges may be used again before the expiry date as long as a new mixing tube is used.

Insert glue cartridge into cartridge gun, remove cap and allow both adhesive components to emerge. Strip adhesive components uniformly and attach mixing tube. Only use mixing tubes supplied with glue cartridge.

Before starting to apply adhesive, allow approx. 1 mixing tube length of mixed adhesive to emerge. Only then apply the mixed adhesive to one side of the bonding surface.

Pot life of adhesive is approx. 60 minutes at 23ºC.

2-component adhesive application: Read the vehicle-specific repair instructions to determine the thickness and positioning of the adhesive bead.

After applying the adhesive, check whether an adhesive component has emerged at the back of the glue cartridge. If yes, break off the bonding procedure. Clean new part. Use new glue cartridge.

Remove contamination caused by adhesive residue immediately.

Hardened adhesive can only be removed mechanically.

Hardening time: Do not move the vehicle before the adhesive has hardened. Check the degree of hardness of the adhesive with a fingernail.

If the adhesive cannot be pressed in any further with a fingernail, the vehicle may be moved (without engine force) for further processing applications (e.g. painting).

Vehicle strength for driving applications is achieved after:

48 hours at an object temperature of 15ºC.

10 hours at an object temperature of 23ºC.

1 hour at an object temperature of 60ºC.

0.5 hours at an object temperature of 85ºC.

IMPORTANT: When using radiant heaters, make sure that the object temperature does not exceed 85 ºC.

Excessively high temperatures will destroy the adhesive.

Disposal of adhesive: Hardened adhesive is disposed of as normal waste.

Empty glue cartridges are disposed of as normal waste.

Non-hardened adhesives and mixtures of adhesive and solvent and the like must be disposed of as hazardous waste.

These regulations apply to the Federal Republic of Germany.

For other countries, comply with the (possibly differing) nationally applicable regulations.

Notes on adhesive K6

IMPORTANT:

Note the following information before starting to apply adhesive!

- Country-specific safety and industrial safety regulations

- Material safety data sheet of manufacturer

- Processing instructions on glue cartridge

Storage: Dry at 15º-25 ºC.

Shelf life: The glue cartridge is marked with a date.

Do not use the adhesive after this date.

Surface pre-treatment: See vehicle-specific repair instructions

Required cartridge gun: OVERVIEW OF GLUE CARTRIDGE GUNS

Preparing the glue cartridge: Do not prepare the glue cartridge until just before applying the adhesive.

The working temperature of glue cartridge must be at least 18ºC.

Pot life of adhesive is approx. 10 minutes at 25 ºC.

Insert glue cartridge into cartridge gun, remove cap and allow both adhesive components to emerge. Strip adhesive components uniformly and attach mixing tube. Only use mixing tubes supplied with glue cartridge.

Before starting to apply adhesive, allow approx. 1 mixing tube length of mixed adhesive to emerge. Only then apply the mixed adhesive to one side of the bonding surface.

Opened cartridges may be used again before the expiry date as long as a new mixing tube is used.

2-component adhesive application: Read the vehicle-specific repair instructions to determine the thickness and positioning of the adhesive bead.

Hardening time: See vehicle-specific repair instructions

Disposal of adhesive: Hardened adhesive is disposed of as normal waste.

Empty glue cartridges are disposed of as normal waste.

Non-hardened adhesives and mixtures of adhesive and solvent and the like must be disposed of as hazardous waste.

These regulations apply to the Federal Republic of Germany.

For other countries, comply with the (possibly differing) nationally applicable regulations.

NOTES ON CLEANING AGENT R1

Use only cleaning agent R1, as other cleaning agents cab be emollient/moistening or may start to dissolve the cathodic dip paint primer.

Notes on handling the high pressure cleaner

WARNING: Only used a high pressure cleaner approved by BMW! Only instructed persons aged over 16 years may work using a high pressure cleaner.

Check the high pressure cleaner and electrical wiring for visible damage.

Only use at a suitable location.

IMPORTANT:

Pay attention to following hazard warnings:

- Danger of injury due to water jet

- Contact with hazardous substances in spray

- Risk of skidding on wet floor

- Risk of stumbling due to hoses and cables

- Comply WITH NOTES AND INSTRUCTIONS ON HANDLING CLEANING AGENTS !

- Risk of scalding when cleaning with hot water.

- On electric or hybrid cars, the safety instructions for handling with hybrid cars are to be complied with.

WARNING: The following personal protective equipment is to be used:

- Safety goggles/face guard

- Suitable gloves

- Apron

- Rubber boots

- Ear protectors

- Safety shoes

IMPORTANT:

Notes on washing a vehicle with a high pressure cleaner:

- Do not wash directly on gaskets and control units during engine washes.

- A minimum distance of 30 cm must be adhered to for tires and tire valves.

- A minimum distance of 30 cm must be adhered to for the soft top and painted parts.

- Do not use if engine is still hot.

- Do not exceed maximum water temperature of 60 degrees.

- Do not spray directly onto cameras/sensors.

- On electric or hybrid cars do not wash on high-voltage components.

Notes on repairing threads

IMPORTANT: Install Helicoil thread inserts so that they are flush with the original thread!

NOTE: Damaged threads may be repaired with Helicoil thread inserts. Observe the PROCEDURE described in the example.

Notes on the water drain hose of the slide/tilt sunroof

The water drain hoses for the slide/tilt sunroof are partially permanently integrated in the body and cannot be replaced individually.

These water drain hoses can only be completely replaced with extensive body repair work (e. g. after an accident).

An individual solution is required for damage that was not caused by an accident.

Notes on using temperature-controlled infra-red radiators

When using temperature-controlled infrared radiators, damage to adhesive bonds, paint and vehicle components can occur when drying spatula and filler.

The temperature sensors in the infrared radiator only operate reliably on large, even surfaces.

On small surfaces such as C-pillars or sills, often only a colder, adjacent area is measured.

This leads to actual surface temperatures of up to 130ºC, even if only 70ºC is set on the infrared radiator.

When the rear side walls are partially replaced by bonding and riveting, these high temperatures can lead to a visible pattern in the area of the joint.

Remedy: Check the surface temperatures on small component surfaces during the drying process with an external temperature sensor.

The general rule is: The surface temperatures must not exceed 85ºC.

IMPORTANT: Do not use infrared radiators on carbon parts! Risk of component destruction.

Opening bonded connections

1. Opening spot-welded adhesive joint OPEN WELDING SPOTS.

WARNING: Extract vapors and gases.

Use personal protective clothing/equipment.

Heat connecting flange with a hot air blower. Heat components to max. 250 ºC object temperature.

Release connecting flange with chisel.

Remove adhesive residue from connecting flange.

2. Opening bonded connections If necessary, open existing PUNCH OR BLIND RIVETS.

Roughly cut out damaged component.

WARNING: Extract vapors and gases.

Use personal protective clothing/equipment.

Heat adhesive flange with a hot air blower. Heat components to max. 250 ºC object temperature.

The component can be peeled with the aid of pliers. Do not damage adjacent components.

Remove adhesive residue from connecting flange.

3. Opening bonded connections on aluminum roofs Procedure is described in detailed in the relevant repair instructions.

4. Opening bonded connections on carbon-fibre-reinforced plastic parts Procedure is described in detailed in the relevant repair instructions.

OPENING BRAZED CONNECTIONS

The "Bonding and Riveting" repair method involves replacing the watertight brazed connection with adhesive.

This gives rise to a new procedure for opening brazed connections.

Grind brazed seam with a belt grinder. This keeps the influence of heat in the area around the brazed seam as small as possible.

IMPORTANT: Never use a gas flame.

All traces of brazing solder do not have to be removed.

Do not grind body panels thin.

Opening rivet connections

Different rivet types are used on BMW vehicles.

1. Opening blind rivets:

1.1 Loosening blind rivets (N1, N2, N7, N8, N9 and N10): Grind off blind rivet head with a belt or angle grinder. Do not grind off base material. Remove rivet remnants with a drift punch.

1.2 Opening blind rivets (N3 and N6): Drill out blind rivet head with a 5 mm dia. drill bit. Do not damage base material. Remove rivet remnants with a drift punch.

2. Opening punch rivets:

2.1 Opening punch rivets by extraction: This procedure is used on the reduced-weight aluminum front end.

Recommended tools and equipment:

- Stud welding apparatus with gas bottle containing inert gas (82 % argon, 18 % CO2).

- Stainless steel stud (sourcing reference via BMW Parts Department image board Aluminum and steel/bonding and welding)

- Universal riveting tool

Grind off paint and dark grey coating of punch rivets.

Position bolt centrally on the rivet and weld on vertically. The area in which the bolts are welded on should be between the two grounding terminals. Position both terminals, if possible, on the top side of the panel on which the rivet is located.

Extract bolt with welded-on rivet using universal riveting tool. Use a large plastic nose piece if not otherwise specified in the repair instructions. Check plastic nose piece prior to use for wear.

Plastic nose piece must rest on sheet metal all round; if necessary, grind off plastic noise piece in collision area.

Do not push riveting tool forcefully onto special-steel bolts.

Do not use riveting tool to bend special-steel bolts.

Pay particular attention to central positioning of the bolt when using the small plastic mouthpiece.

Follow the equipment manufacturer's instructions for use.

2.2 Opening punch rivets by drilling out: Drill out rivets with a 6 mm dia. carbide drill bit.

Punch rivets can be drilled out on both sides. When drilling from the protruding rear side, spot-drill the rivet shank only and remove the rest with a rivet punch.

NOTE: Sand down and even out remaining burr on the rear side. Deburr bore holes.

Use a drift punch to remove punch rivet remnants in the aluminum (risk of corrosion).

Clean vehicle to remove swarfs (risk of corrosion).

Opening welded connections

1. Components made of steel:

1.1 Opening welding spots (resistance pressure spot welding): Sheet steel panels made from high- and super-high-strength materials make great demands on the tools used.

Only with special carbide milling cutters can welding spots be drilled out on these sheet panels.

Use BTR/BOR milling cutters only in conjunction with Vario Drill spot-weld remover. Sourcing reference for spot-weld remover and BTR/BOR milling cutters.

- Procedure:

If necessary, surface-grind existing unevenness with a belt or angle grinder in the area

around the welding spot.

Set punch mark in center of welding spot. Set 8 mm dia. welding spot drill bit on punch mark and drill through top metal sheet.

NOTE: Because the welding spots may have surface-hardened, grind them if necessary with an angle grinder and paper grinding disc.

Use a chisel to separate the sheet metal flange and remove the component.

Follow the special procedure for SPOT WELDS.

1.2 Opening MAG weld seams and MIG brazing seams:

- Procedure:

Grind off weld seams with a belt or angle grinder. Do not grind the base material thin.

Use a chisel to separate the sheet metal flange and remove the component.

1.3 Opening laser weld seams: Laser weld seams are used in the roof outer skin area.

- Procedure:

Roughly cut roof outer skin in the roof channel to improve accessibility.

Place angle grinder with grinding disc on laser weld seam and grind through top metal sheet.

Be careful not to cut through and damage sheet metal underneath.

Remove sheet metal flange.

2. Components made of aluminum:

2.1 Opening MiG weld seams:

- Procedure:

Grind off weld seams with a belt or angle grinder. Do not grind the base material thin.

Do not use a chisel.

Remove component.

Overview of adhesive cartridge guns

Adhesive gun 83 19 2 149 522

Usable for adhesives K4, K5a.

Usable for BMW 2K polyurethane foam.

Including insert 1:1 and 2:1.

Adhesive gun 81 49 0 443 166

Usable for adhesive K3.

Adhesive cartridge gun 81 49 2 213 059

Usable for adhesives K1, K5b, sealant D1/D2, window glass adhesive and all 310 ml Euro cartridges.

Adhesive cartridge gun 83 30 0 494 836

Usable for structural foam HS2.

NOTE: Special tool number 41 3 010

Adhesive cartridge gun 81 49 2 355 475

Usable for adhesive K2 (2x290 ml glue cartridge)

OVERVIEW OF CONSUMABLES

1.0 Adhesives

1.1 Primer/activator

1.2 Cleaning agent

1.3 Fillers

2.1 Rivets

2.2 Plastic nuts

3.0 Primer/paint spray aerosol

4.0 Sealant

5.0 Cavity preservation

6.0 Cavity foam

7.0 EMC screw (electromagnetic compatibility)

8.0 Twist drill

9.0 Grinding material

10.0 Spacer

Position of shaped parts for cavity sealing

Cavity sealing is carried out in specific body areas in order to reduce interior noise and to reduce condensation.

To do this, shaped parts are inserted in the cavities. These shaped parts adapt themselves optimally due to heating of the body to approx. 180 ºC by expansion to the shape of the cavities.

Because it is not possible to heat the body to this extent for a body repair, a different procedure .

Punch rivets

The "Bonding and Riveting" repair method involves the use for the first time of punch rivets in the repair. This requires new tools and procedures.

The punch rivets are matched in size to the material thickness and quality used at the respective connection point.

1.0 Recommended tools and equipment

- Punch rivet tool (05 03 09 (535))

Setting punch rivets:

- Refer to the vehicle-specific repair instructions for the punch rivet size.

-

Mark the positions of the rivets on the vehicle. Set punch rivets at roughly equal spacings.

Punch rivets do not require a predrilled hole. They are pressed directly into the full material.

-

Insert punch rivet in riveting die. Position punch rivet tool on sheet metal parts to be riveted.

Riveting direction: Always from new part to used part.

Deviations are specified in the vehicle-specific repair instructions.

- Rivet punch rivets with punch rivet tool. In the meantime clean riveting die and matrix if fouled with adhesive.

- Seal punch rivets in moist area (e.g. wheel arch or carrier support) on both sides with SEALANTD1 (risk of corrosion).

- Seal cavities after painting vehicle with CAVITY SEALANT (risk of corrosion).

Quality standard

-

The overall requirements relating to a vehicle can only be implemented by including "all" components.

This applies in particular to the body. With regard to an optimum crash result, it is necessary to maintain the structural measures.

The procedures described in the repair instructions must be complied with. Deviations are only permitted after arrangement with and approval by BMW.

The use of non-approved repair steps or tools may have serious consequences for the structure of the vehicle (e.g. in the event of a crash). In the end, this can result in safety and product liability risks which cannot be calculated.

Corrosion protection measures during and after repair work are vital for ensuring the vehicle retains its value.

-

For repair work, only use original BMW/MINI parts, or parts that are of an equivalent quality, and

approved auxiliary materials and operating fluid.

For repairs that are settled by a warranty or goodwill, only original BMW/MINI parts may be used.

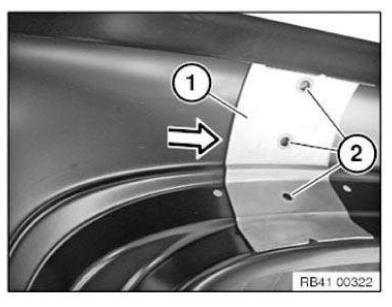

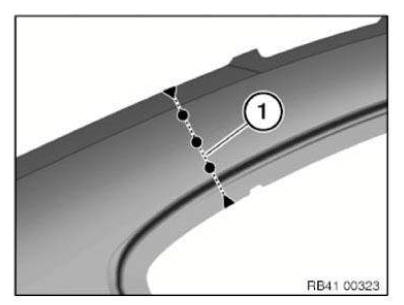

Reinforcement plate (bonded)

In the case of a partial replacement piece, a body component is cut at a point described in the repair instructions.

A reinforcement plate is bonded in to ensure sufficient strength.

Observe notes on REPAIR STAGE 2.

NOTE: The following graphics serve as general illustrations of reinforcement plate repair work. They apply to sectional repairs to the structure.

Mark component in accordance with measurement a and cut.

Preparation of new part: Cut new part (1) in accordance with cut on vehicle and if necessary adjust to fit with straightening attachment or universal mount.

Make reinforcement plate (1) from trim of new part (2).

Length of reinforcement plate is 80 mm.

Slide reinforcement plate (1) half-way into component on body and fasten with 2 self-tapping screws (2).

Adjust new part (1) to fit and set 4.3 mm dia. bore holes (2).

Remove new part again.

Release self-tapping screws (3).

Remove reinforcement plate.

Drill out bore holes (3) for screws to 4.3 mm dia.

Deburr all bore holes.

IMPORTANT: Do not grind new part and body in area of bonding surfaces.

Installing reinforcement plate

Clean all bonding surfaces with cleaning agent R1.

Apply adhesive (1) to reinforcement plate bonding surface.

Carefully slide reinforcement plate half-way into body component (2).

IMPORTANT: When joining reinforcement plate, make sure there is sufficient adhesive on bonding surfaces.

Rivet reinforcement plate (1) up to half-way with blind rivets N3 (2).

Apply adhesive (1) to reinforcement plate bonding surface.

Install new part (1) with straightening attachment or universal mount and rivet with blind rivets N3 (2).

After adhesive has hardened, flatten adhesive area and seal blind rivets.

Reinforcement plate with stud bolt (bonded)

In the case of partial replacement, a body component is cut at the point described in the repair instructions.

A reinforcement plate is bonded in to ensure sufficient strength.

Reinforcement plates are available as new parts and must also be used .

NOTE: The following graphics serve as general illustrations of reinforcement plate repair work. They apply to the sectional repairs on the outer skin which are produced using the adhesive joining method.

Overview of reinforcement plates:

- Reinforcement plate, sill

- Reinforcement plate, C-pillar

- Reinforcement plate, universal

- Reinforcement plate, C- or D-pillar

- Nuts (not shown)

- Plastic nut dia. 18 mm, part number 07 14 1 943 122

- Expansion nut dia. 22 mm, part number 07 14 7 169 847

Mark component in accordance with dimension a and cut.

Preparation of new part: Some of the reinforcement plates are oversized.

If applicable, it is necessary to rework reinforcement plates at the edges or cut them to size until the reinforcement plates are in tension-free contact with the outer skin.

It must be possible to push the reinforcement plates into the body without shearing off the adhesive.

Adjust reinforcement plate (1) to fit in component (2) on vehicle.

Make semicircular recesses (3) for the stud bolts (4).

Diameter of recesses approx. 10 - 12 mm.

Secure reinforcement plate by screwing on nuts (1).

Fit new part (2). Make recesses (3) in new part in a semicircular shape.

Diameter of recesses approx. 10 - 12 mm.

Remove reinforcement plate again.

NOTE: Width of joint between new part and component on vehicle approx. 5 - 8 mm (at least 30 mm flange width per side).

Chamfer cutting edges (1) on joint by grinding.

- Component on vehicle

- New part

Installation note:

If the cutting edges have not been sufficiently chamfered, there may be voids in the paintwork after painting.

IMPORTANT: Do not grind new part and body in area of bonding surfaces.

Procedure for using universal reinforcement plate: The universal reinforcement plate needs to be adapted. The plate must be divided if the distance between the pins is too great.

Dimension a is between 40 and 80 mm depending on the space available.

Secure plates with N4 punch rivets.

NOTE: Ensure the rivet is positioned correctly! Rivet head is on the adhesion side!

Rivet the plate to the inside of the flange!

Installing reinforcement plate

Clean all bonding surfaces.

Apply adhesive to reinforcement plate in area (1).

Apply more adhesive in the radii to avoid air pockets.

Apply additional adhesive to the outer skin around radii.

Carefully slide reinforcement plate into component on vehicle and secure by screwing on nuts (2). Screw on nuts a few turns only.